No really. They’re all well and good when you’re blowing them into the air on a sunny summer day, but when they’re in your mould? Sucktastic.

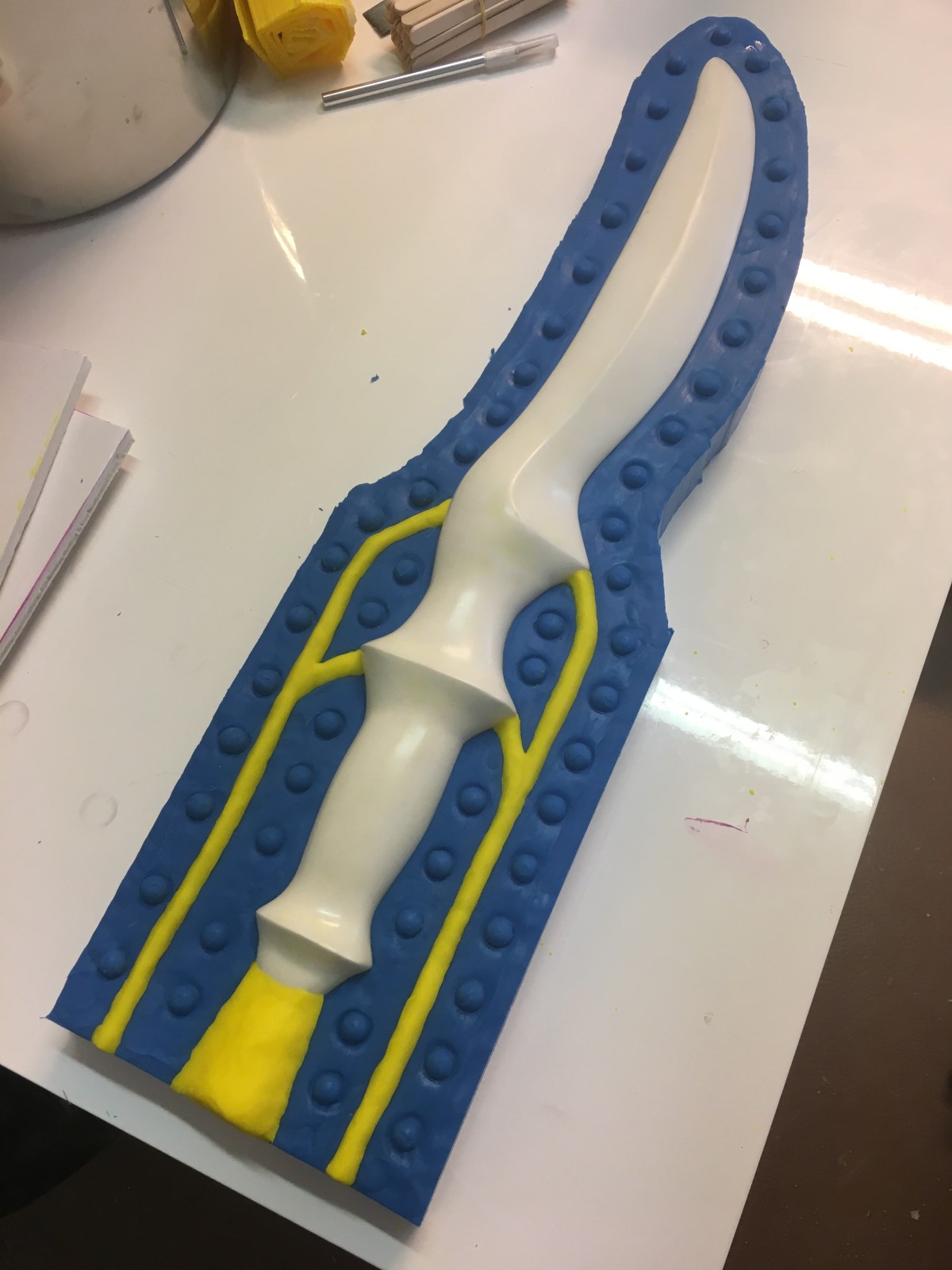

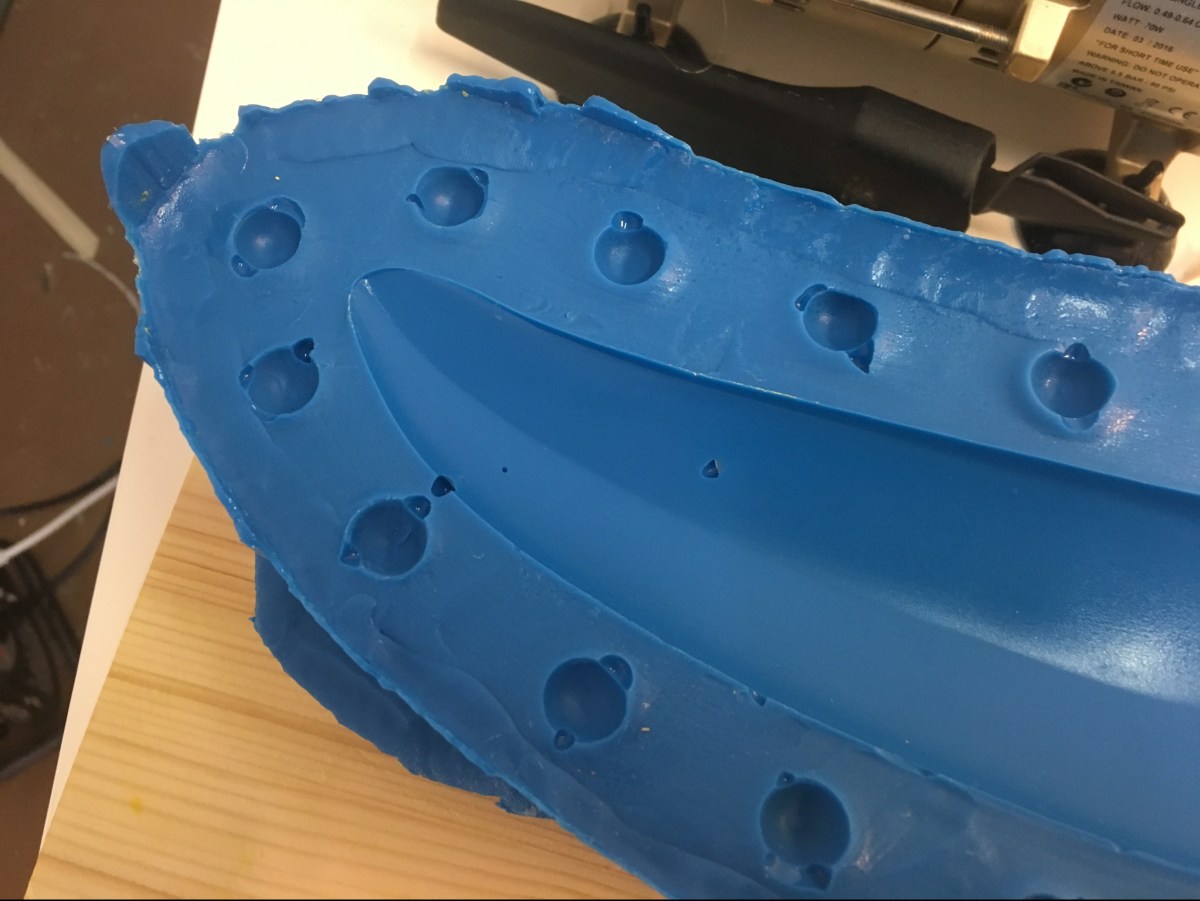

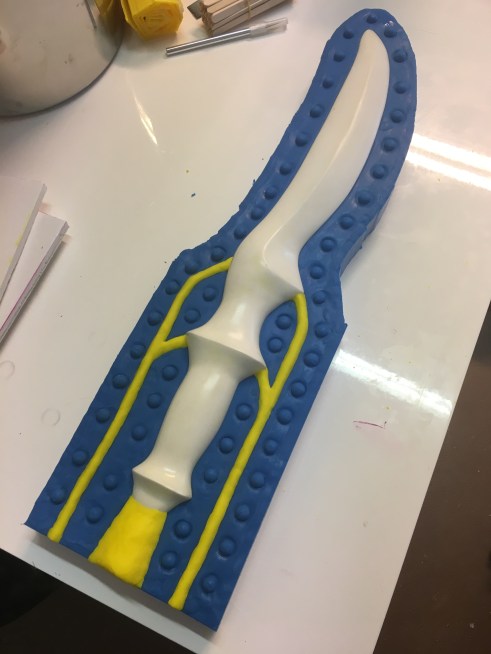

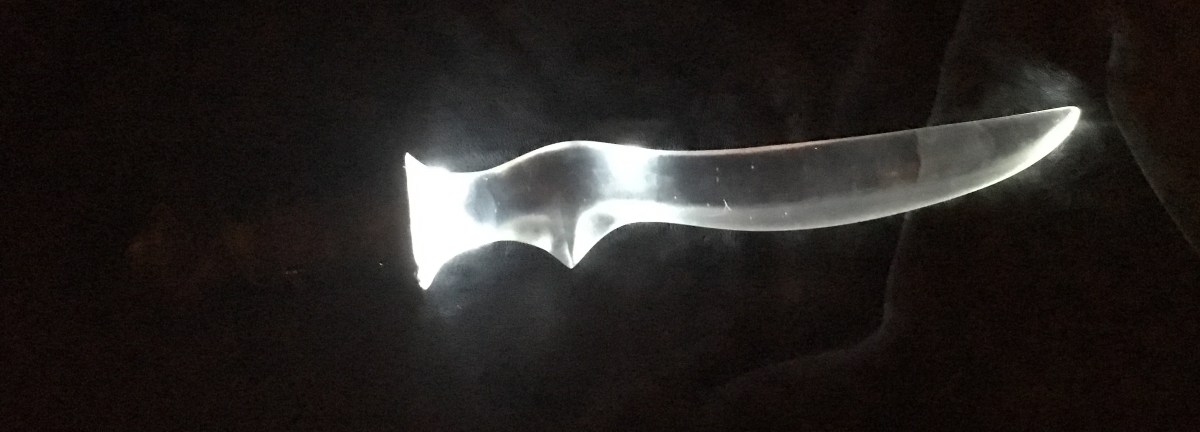

This will not produce a lovely smooth sword. This will produce a mostly lovely smooth sword with weird little warts all over it. Unacceptable.

So why is it like this? What happened? Well, it turns out that my workshop was hotter last week than I thought it was. Zhermack’s beautiful ZA22 silicone’s normal working temperature is 24 degrees Celsius. That means that, at 24 degrees, this lovely blue goo will set in 60 minutes. If it’s colder than that, it will set more slowly giving you a longer working time. But if it’s hotter …

The setting time is dramatically faster! I was in the middle of degassing it when it started turning into a sticky glop the consistency of cookie dough. I knew I was in trouble. 3 litres of silicone is NOT cheap. I pulled it out of the vacuum chamber and poured it as fast as I could. It was sticking to the inside of the container and I had to shove my hand into it (gloved of course) to pull out the rest because it wouldn’t flow anymore. It was like working with a huge mass of chewing gum.

As you might guess, bubbles got trapped in the silicone because it was just too viscous (thick) for the air to escape.

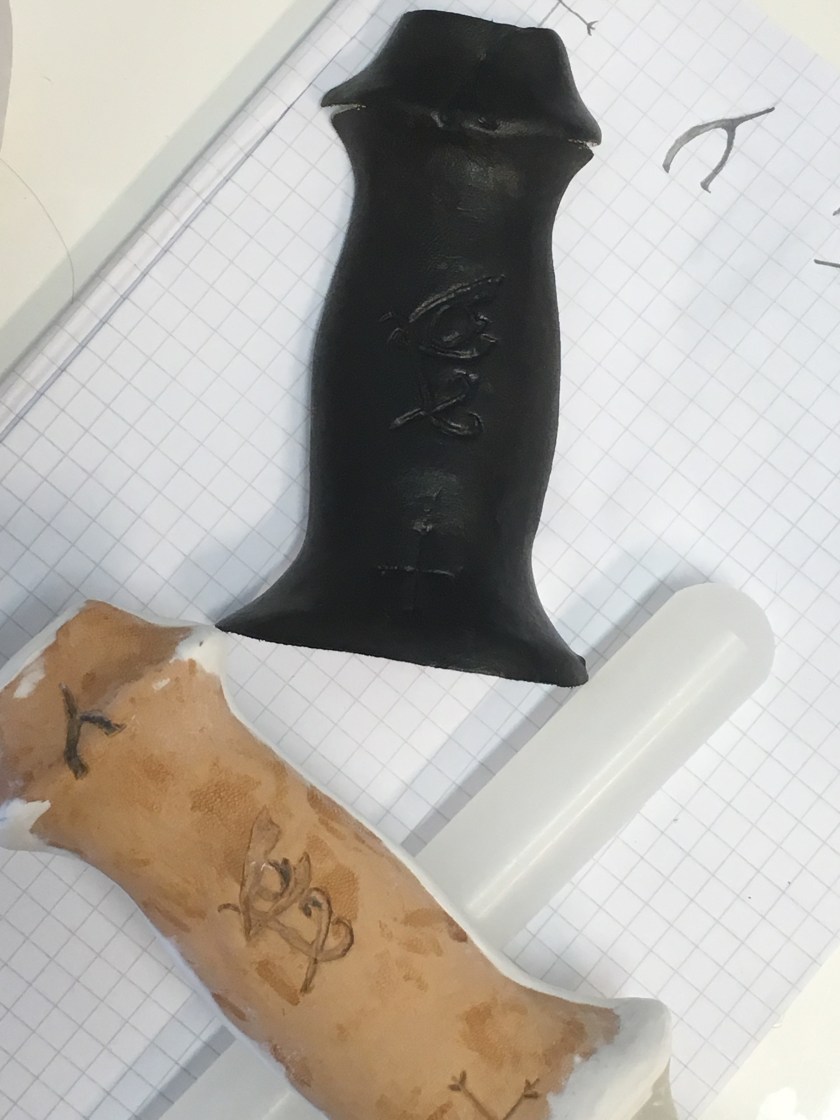

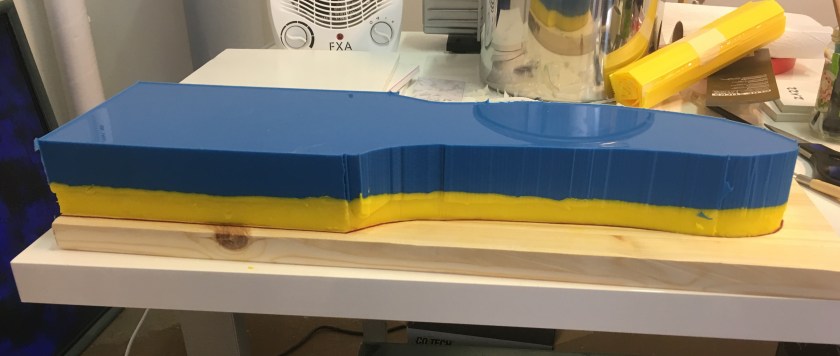

What to do? That right there is about a 108 Euro mistake. Yikes. Well, the important bit is the mould that immediately touches the sword I’m going to be casting. That has to be perfect. The rest of it? Meh. Nobody’s going to see any of that. So I decided to cut out the middle section of the mould and re-pour it instead of re-pouring the entire thing.

I should have re-poured the entire thing.

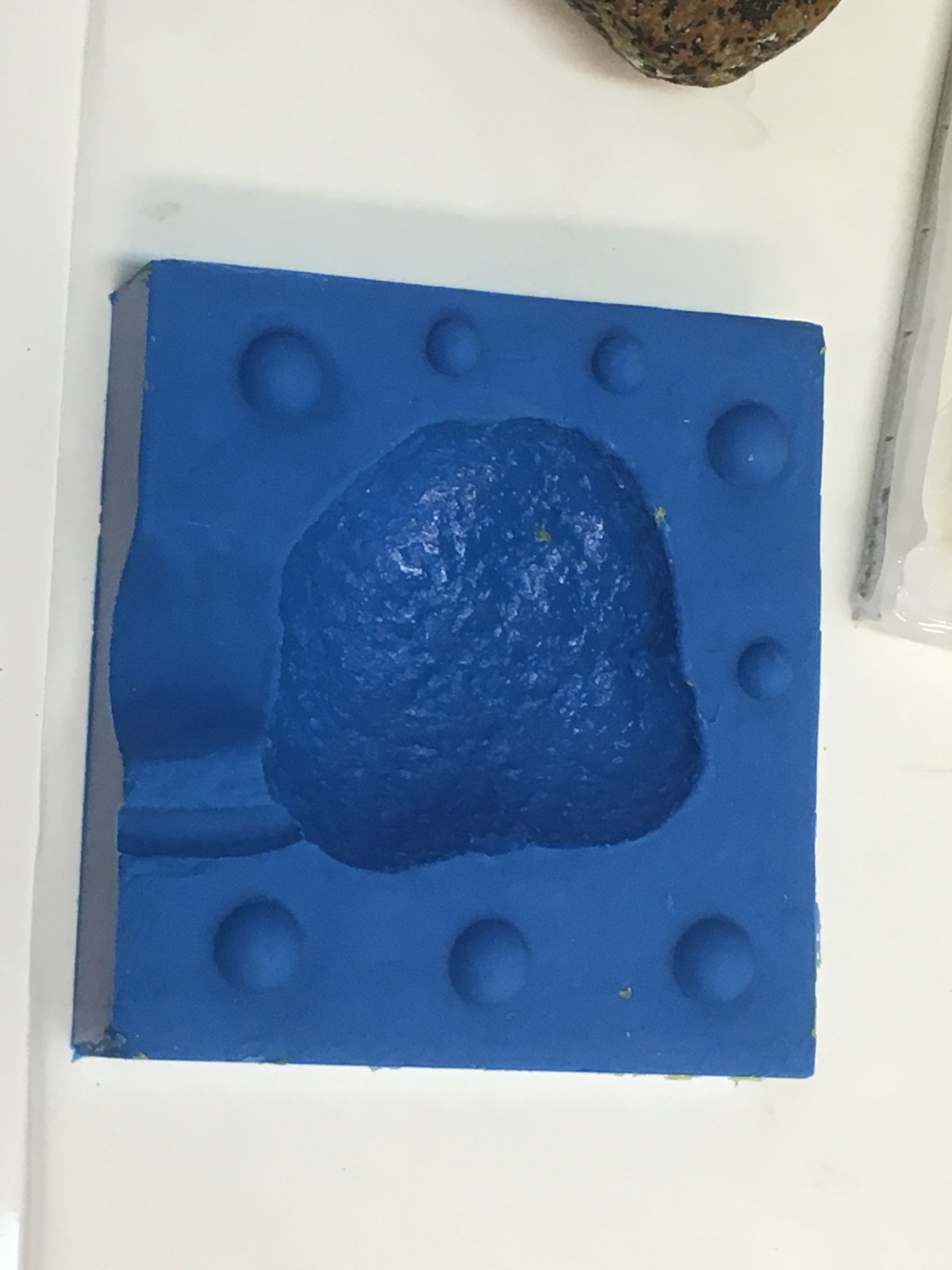

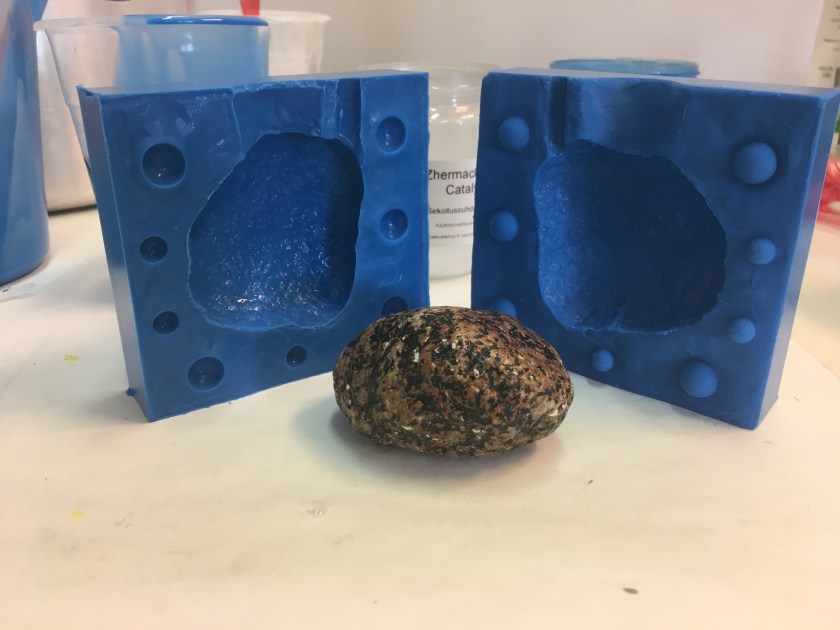

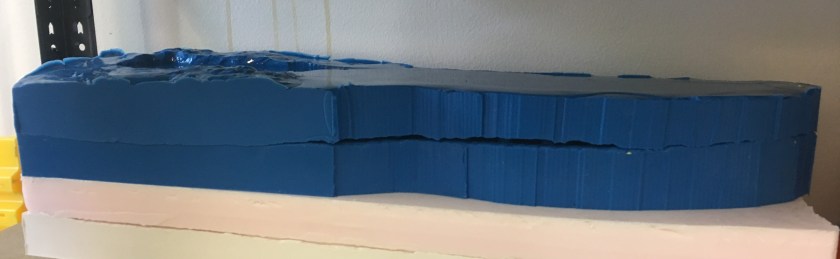

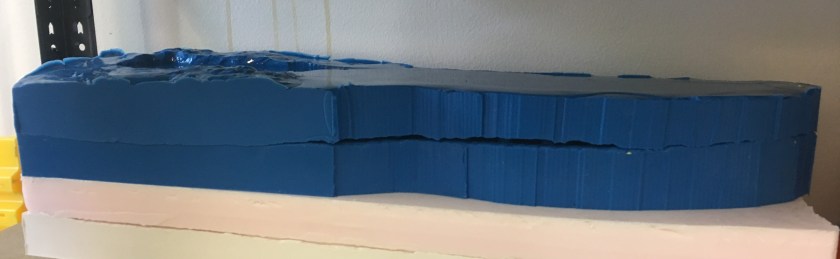

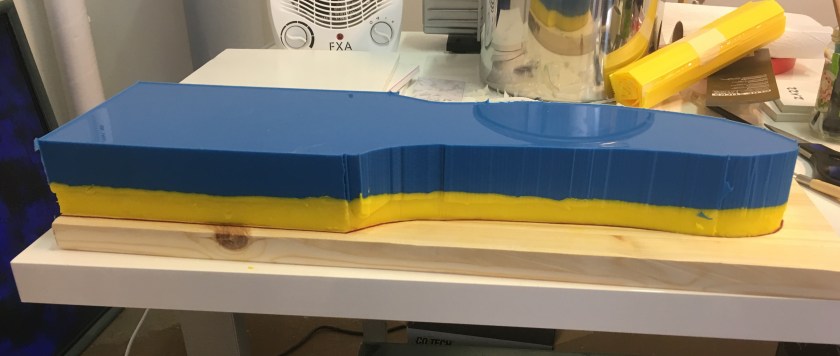

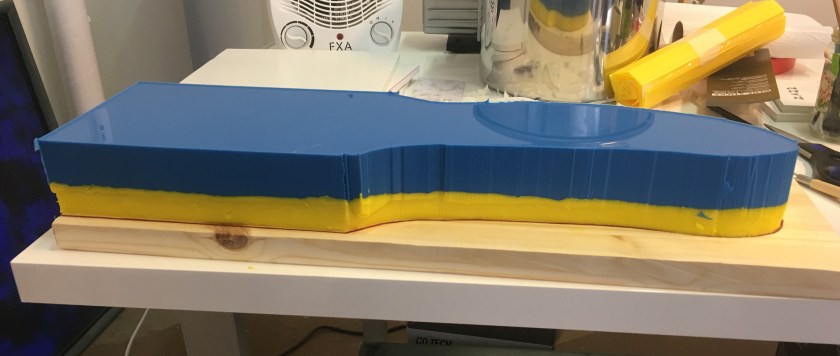

So what’s this crazy deformed blue crocodile thing? That’s the mould. You might notice a slight gap there in the side.

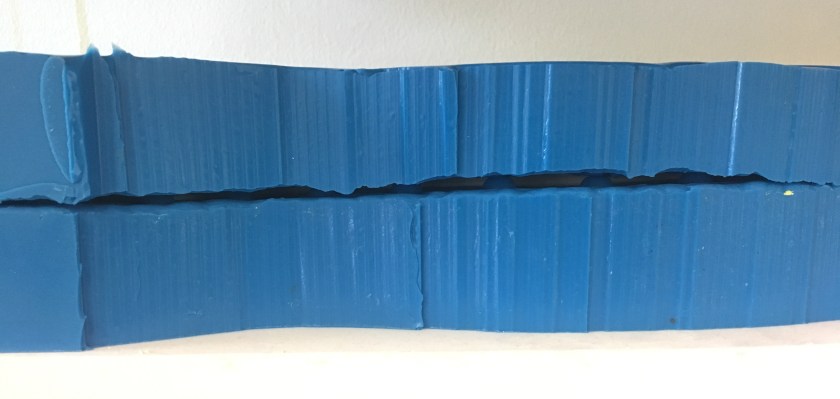

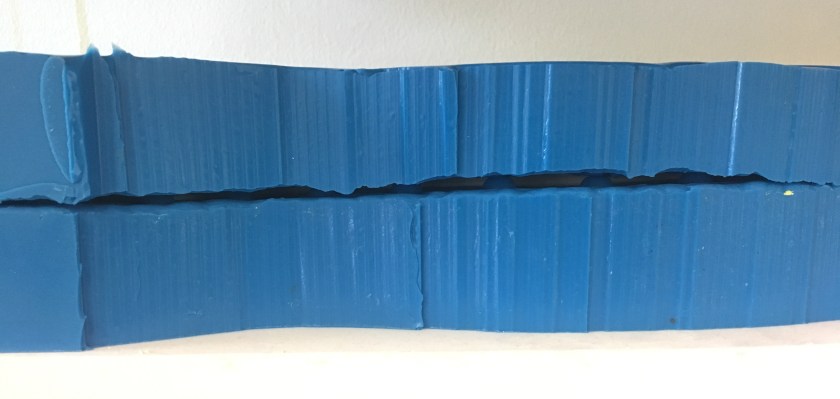

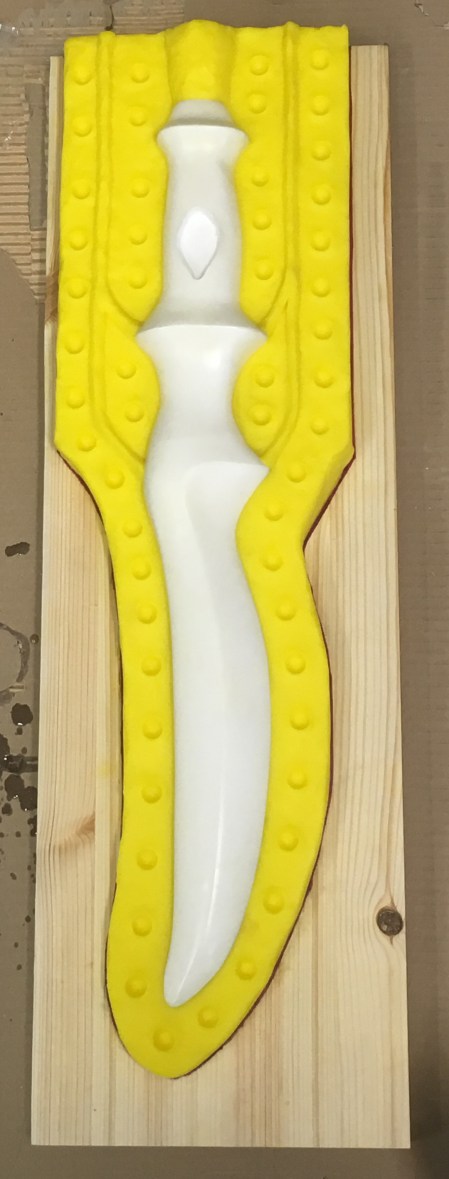

And by ‘slight gap’ I mean it’s wide enough to see the model sword inside the mould when it’s closed. So if I used the mould like this, all the resin would leak out the side. Why did it do this? Well, you might notice that the left side of the mould there has no gap. Let’s have a top-down view so you can better see what I’m about to explain.

The top half of the mould is where hilt is and also where all those funky vents and the pour spout is. That makes it thicker than the funny banana-shaped bottom half where the blade is. Of course, the thicker bit is heavier. So when I poured the silicone into the middle section that I chopped out, the heavy top half stayed put, but the lighter bottom half floated! Since it only lifted up about a centimetre, I didn’t notice the movement.

The silicone I poured into the middle part to re-mould the sword bonded nicely with the rest of the silicone mould around it. Yay! But the silicone that crept in between the two halves of the mould didn’t stick to either side even though I cleaned one of them really, really well, and sealed the other very thoroughly. It would not obey my wishes and stayed a crazy blue flap just hanging out in between the two halves of the silicone sandwich.

So what do I do? Uhh … well I don’t have enough silicone left to re-pour the half of the mould I messed up. I’m not completely sure my budget can withstand another silicone purchase this month. We’ll have to see. So I’m going to attempt a weird “spacer” where the gap is so I can at least use the mould until I can re-pour the other side. What I’m going to make that out of is still up for debate. Possibly some kind of polymer plastic. Possibly rubber of some kind. Possibly uh … I don’t know. I’m going to experiment with many kinds of goo and see what works.

I have learned a lot from this mistake so it’s not entirely doom and gloom. So I’m trying to look on the bright side. It’s still frustrating for me cause I really wanted to be casting my first sword in the new mould this week. Oh well. The Iron Sisters are stubborn for a reason! Don’t give up!

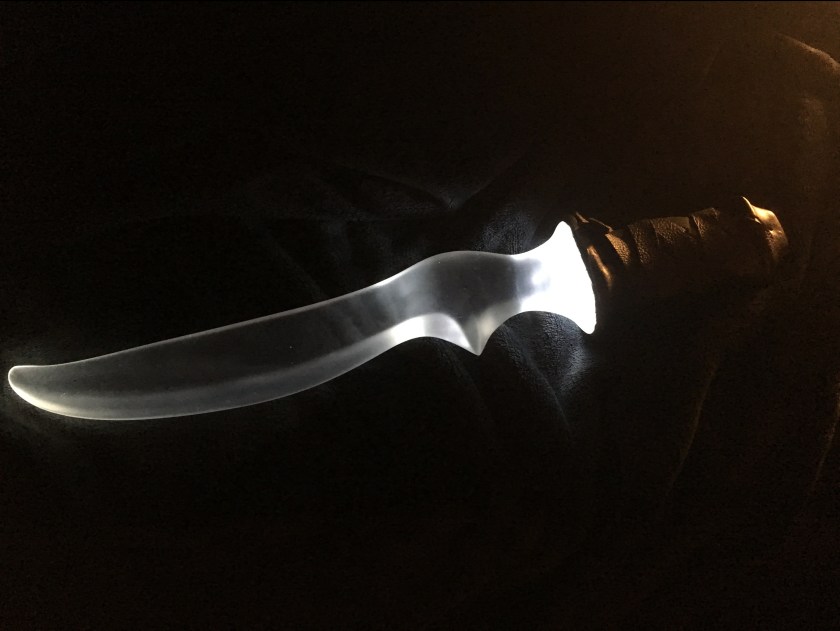

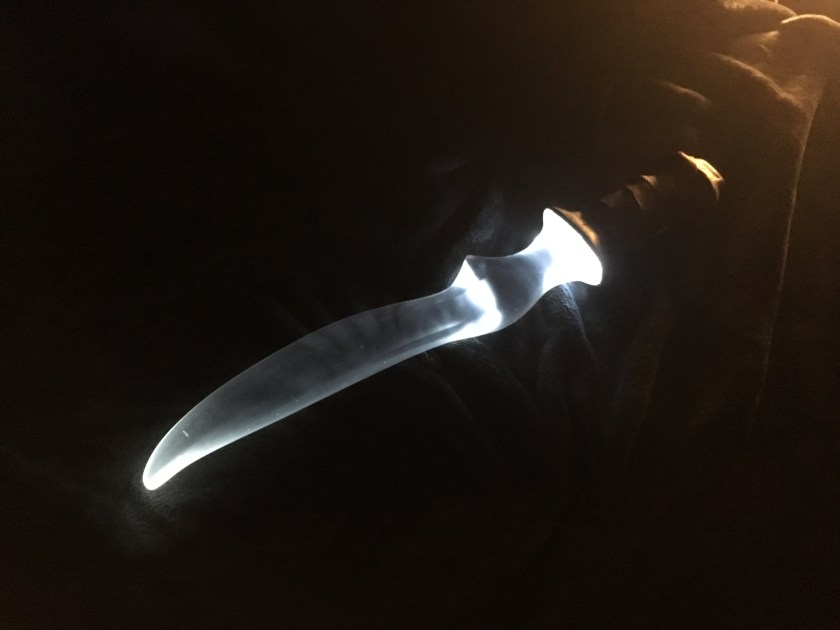

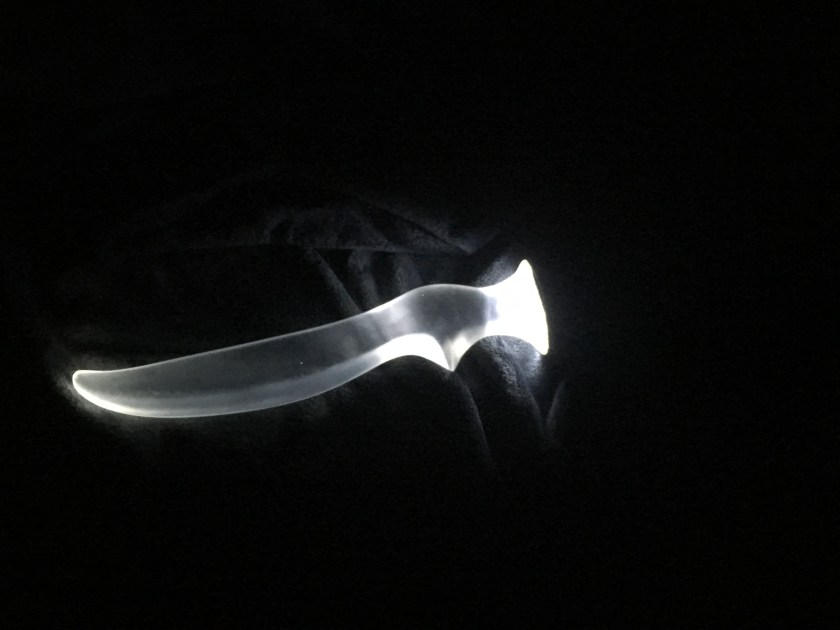

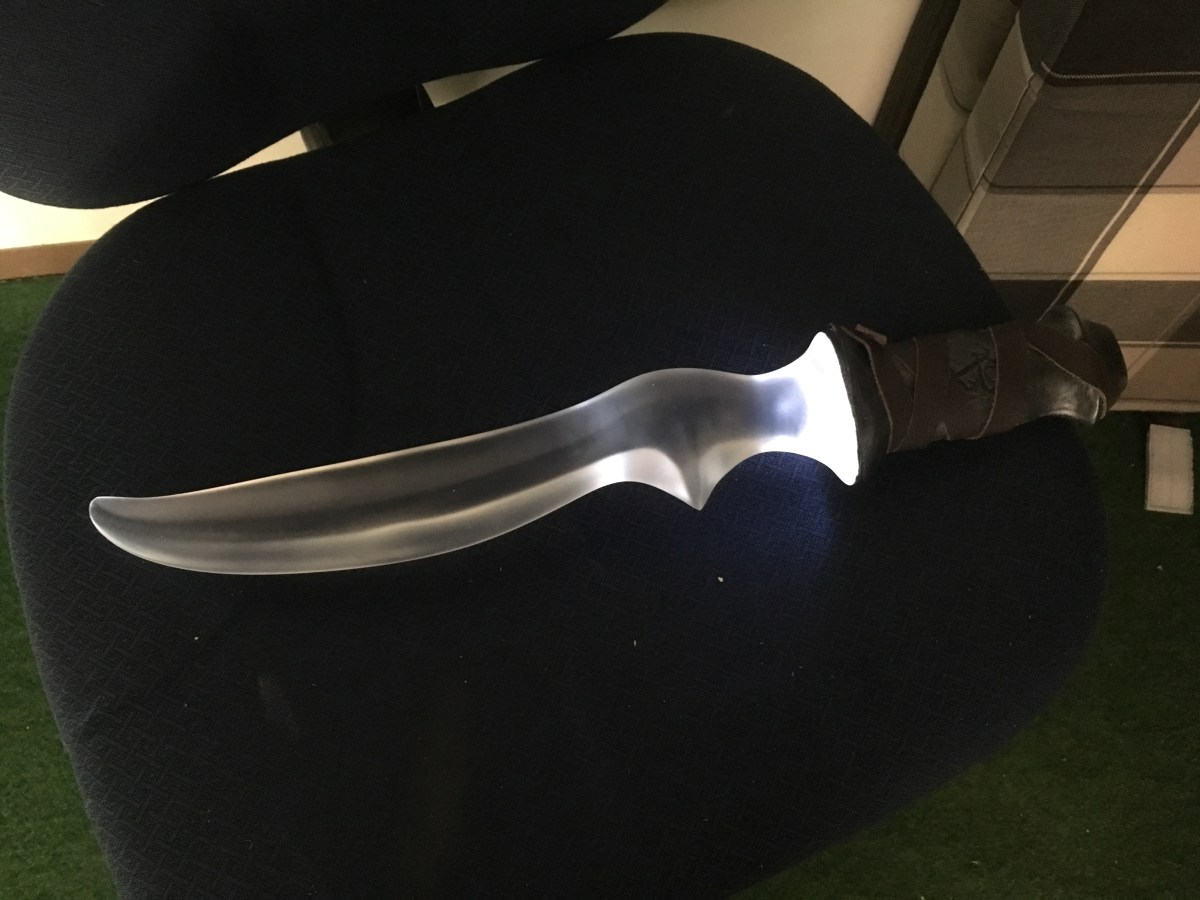

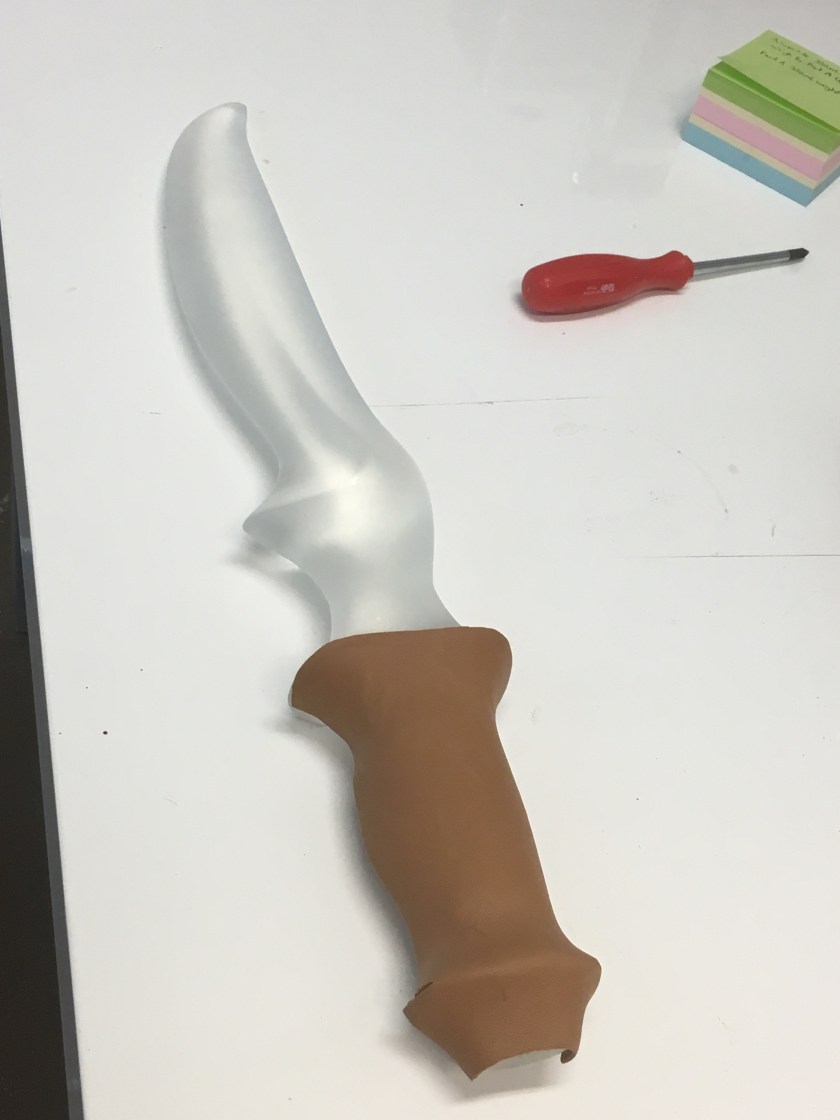

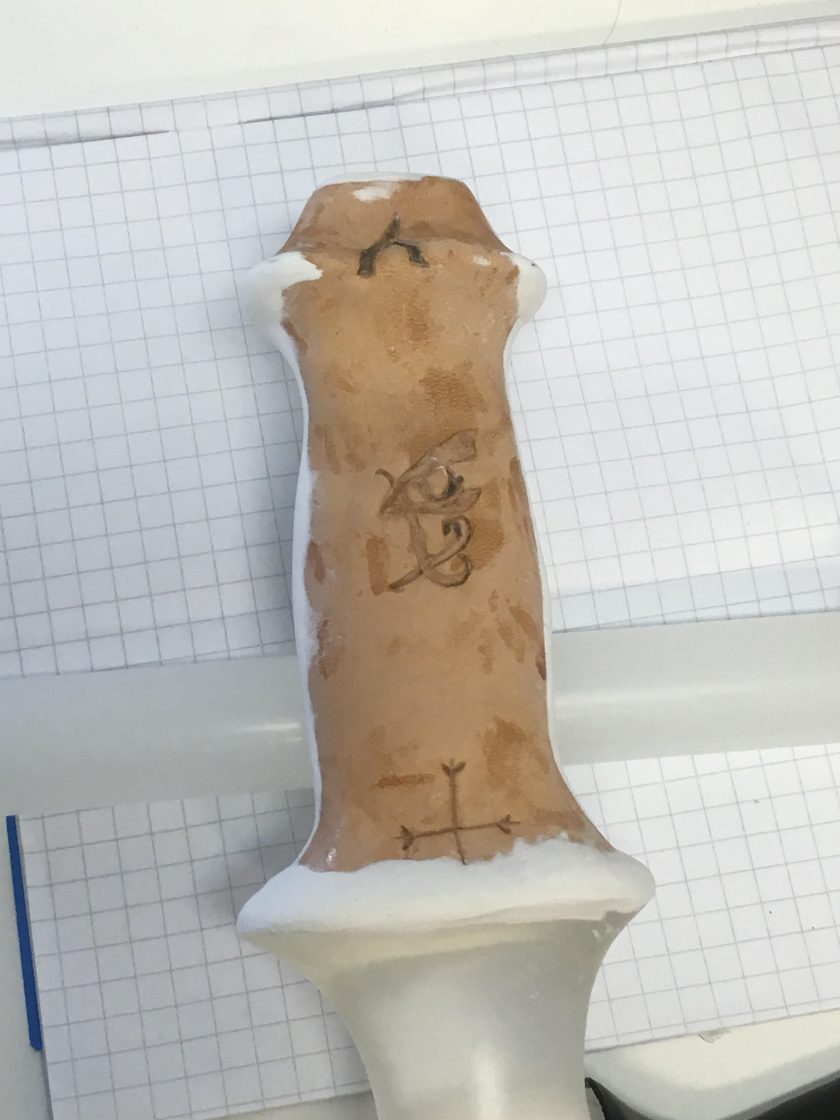

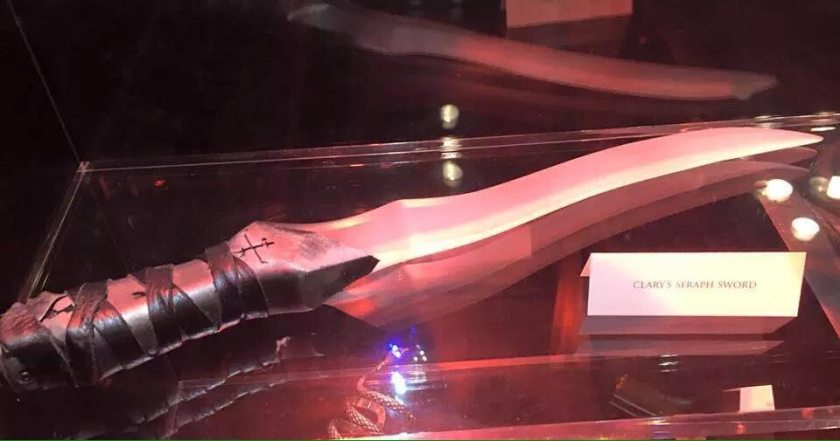

Stay tuned for more exciting news including a brand new sword I just finished. I’ll give you a hint: it has nothing to do with Shadowhunters!

![IMG_2546[1]](https://heythisismyjob.com/wp-content/uploads/2018/05/img_25461-e1525677645478.jpg?w=840)

![IMG_2550[1]](https://heythisismyjob.com/wp-content/uploads/2018/05/img_25501.jpg?w=573&h=764)

![IMG_2528[1]](https://heythisismyjob.com/wp-content/uploads/2018/04/img_25281-e1525072622185.jpg?w=840)

![IMG_2524[1]](https://heythisismyjob.com/wp-content/uploads/2018/04/img_25241-e1525073198419.jpg?w=840)

![IMG_2523[1]](https://heythisismyjob.com/wp-content/uploads/2018/04/img_25231.jpg?w=840)