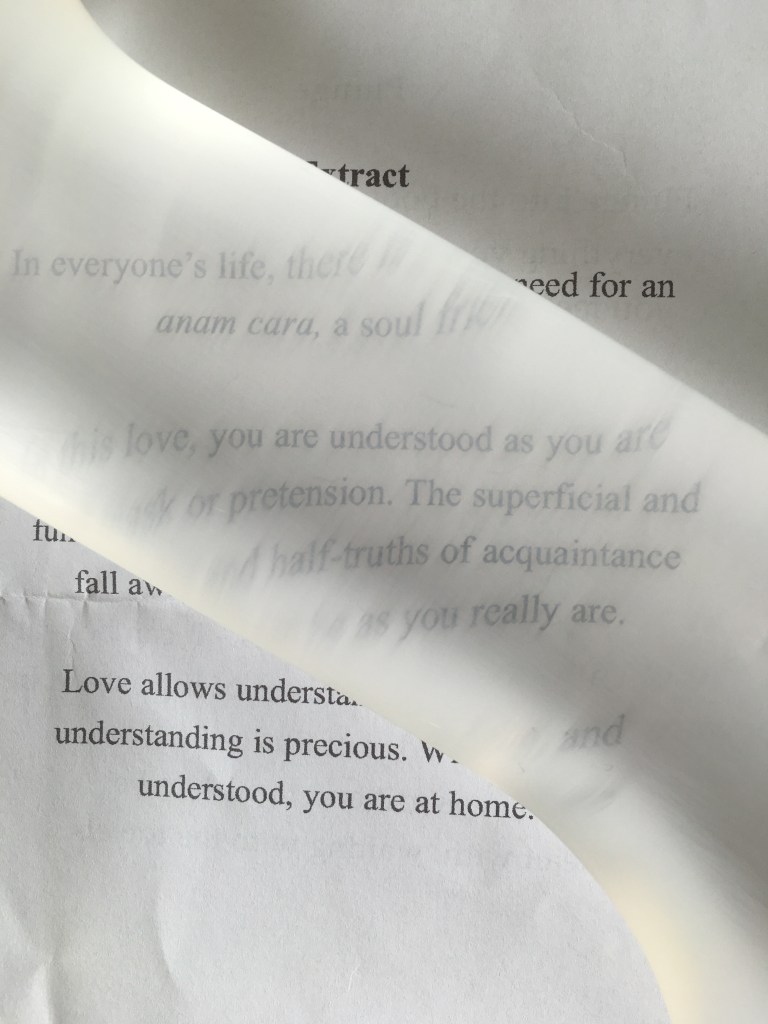

The Last Bite

My dreams are strange. Sometimes I slip between worlds by accident. Between lives. Maybe I don’t really go anywhere. Maybe it’s just random synapses of my brain firing off while I rest, idling before the new day. Whether you believe it or not, I’d like to share one of these wanderings with you because I think there’s something here that belongs to you.

I had an argument with something that called itself Death. I’ll retell it to you as well as I can remember ….

I’m in one of those reincarnation dreams I have so often. Rewinding and fast-forwarding through lives and exploring the spaces between. Longing for loved ones I’ve never met and trying to find the exact place where I left them just to see them again. Missing the me I’ve never been before and trying to figure out how to put him back together.

I’ve lost my wife again for the hundredth time and I’m trying to get back to her in the right shape so she will recognize me, and suddenly I’m in darkness. Complete darkness. What happened? Did I break the dream somehow?

The darkness isn’t empty. It doesn’t feel alive but it has a weight to it. A presence. A cold black velvet fog that slows my thoughts. It pulls the energy straight out of my flesh and leaves me as a chilled pile of wet clay. I’m so tired. I hate being tired in my dreams. It doesn’t seem fair.

I can’t conjure up anything to see or any path to explore. I can’t think of anything I would want to do anyway. Too much effort. It’s all too much. I just want to melt into the darkness and not think anymore. Not be anymore.

Ah. This is familiar.

“Hello Depression,” I sigh into the black.

I feel it smile. I can’t see the expression but I know. Like I’m sitting in its mouth and I can feel the walls twist.

“Go away,” I say. “I want to go back to my dream.”

“No,” it replies. Its voice ripples. A gust of wind across an almost-frozen lake. I can’t pick out any one tone. It fluctuates. “You came here. You go away,” it continues.

I’ve overslept my alarm. I know that. Being winter in Finland, there will be no sunshine. We will be buried in snow, even more than there was when I went to bed. The street lights might even be on already. What can I even do with my day that matters? I’m an unpublished writer with crippling mental health issues, unable to even hold a “real” job.

It’s still smiling. “I’ve trained you so well,” it says, amused. “I hardly have to do anything anymore these days. You defeat yourself for me before you even get out of bed. A little nudge and you ruin everything for yourself.”

I think about the chores that need doing. That would at least be useful to someone. But I’m tired. I haven’t even opened my eyes yet and I’m tired. “I don’t want to wake up,” I mutter.

“Then don’t,” it says. “You know it’s pointless. Even if you finish a chore, it will need to be done again the next day. The next hour even. You can’t win. Even at the small things.”

“Just shut up,” I say and I sit down. I have no idea what I’m sitting on in the dark and I don’t want to think about it.

It says nothing. The silence yawns. It doesn’t help. I can still feel it watching me. I’m angry and the anger warms me. Maybe I can make some use of the situation. I give it a try.

“What are you anyway?” I ask it.

“I am Death,” it says. “I am the Great Consumption. The Inevitable. The End.”

“No you’re not.” I fold my arms in defiance. “Death isn’t malicious. Death doesn’t go around killing people on purpose.”

“Doesn’t it?” it asks me.

“No.” I persist. “Not for fun. Not like you do. Besides, people die of lots of things, not just Depression.”

“It’s all the same in the end,” it says. I feel it shrug. “I devour everything.”

“I don’t believe you,” I tell it. “You lie all the time.”

“Keep telling yourself that if you like,” it says. “It won’t change the outcome. You believe me anyway and you continue doing what I want regardless of how much you protest. I always win. I win every time someone lets out their last breath. All I have to do is wait and I win.”

“Then why do you always have to try so hard?” I snap back.

For a moment, it doesn’t answer. “What do you mean?” it says finally. The amusement is gone from its voice, replaced by something prickly.

“Why do you expend so much effort circling around me all day?” I press my question. “Why do you have to keep chewing on me like that? Telling me I’m garbage and that nothing I do matters and that it’s all too much effort and nobody will appreciate it anyway. It’s a constant, never-ending stream of pressure from you, every day, all day. Why do you go to so much trouble if all you really have to do is wait?”

It says nothing but I can feel it thinking. Something in the mist rolls and boils against my skin. It’s cold and damp as ever, but the warmth in my chest is growing. It gets to gnaw on me until the day I die so why can’t I turn around and bite it back just this once?

“Wait and win, isn’t that what you said?” I turn my legs and sit up on my knees. “If victory is inevitable, why don’t you just sit back and wait for me to die like everybody else? If you really are Death like you say you are, then you’d just wait to receive the fallen when their time is done. But you don’t.” I clench my fists.

“You’re always circling around, whispering your trash in my ears, pushing down on me, sucking out my energy, filling my head with fog and lies. Why do you have to try so hard?” I thump my fists against the ground and it hurts my knuckles. Like punching ice.

I’m exhausted and I’m panting like I’ve run for miles but my breath is hot and the cold dark is barely touching me now. Just little wisps against my shoulders here and my feet there. I can’t see anything, but … is it pulling back from me?

“Because it’s fun to watch you struggle,” it whispers. The voice is above me, I think. The little hairs on the back of my neck stand up. “Everyone tries different strategies against me. The fight is exciting. They always fail, but it’s interesting to see exactly how it will happen.”

It brushes against me on either side like wet wings made of cobwebs. I wrap my arms around myself and rub my skin with my hands, trying to banish the numbness. How many times have I dove headlong into that vacuum of feeling just to escape that damned voice? I don’t want to give it the satisfaction. Not this time.

“So, you just like seeing how the story plays out then?” I ask. “A little tragedy play with your meal?”

“Now you’re getting the idea,” it says. I feel the smile again. The fog caresses my back like a dead fish. “It adds to the flavour. Each death is a unique dish.”

“You’re lying again,” I snarl. I force myself up to my feet. I wobble. So tired. So weak. I can hear little chuckles hovering around me in the darkness but it makes the anger in my gut flare. “Life is hard enough without your interference.” The tittering gets louder, as if more voices are joining in.

“If you really enjoyed watching me struggle, you’d want it to go on for as long as possible. You have all the struggles of every living thing to watch. If you wanted an epic battle, each and every life is a saga of trials and victories and defeats. But you want to cut my story short. Why?”

Silence. I turn in a slow circle, wanting a face to address, but there’s nothing to see. The darkness watches.

“If you really are Death and you tell me that struggling makes people delicious, then why don’t you want me to live as long as possible?” I shout my question and there’s enough space around me to echo. It’s there still. I can feel it in the air, the way my voice vibrates and comes back to me. But it’s not touching me anymore.

“You should want me at full power, accomplishing my goals, hoping, praying, failing, getting back up again, cursing, striving, building a legend for your banquet instead of settling for the dregs of someone too tired to even try.”

There are tears on my face, I realize. I’m too afraid to wipe them away because they’re warm and alive and they feel like something real. Memories of all the mornings that passed me by while I hid under the blankets are choking me. The exhaustion. The fear of failure. The disappointment. The disgust of catching a glimpse of myself in the mirror. The grey hairs marching through my scalp, recruiting more and more as I run out of time to create just one. god. damned. thing. for people to remember me by.

It’s all wrapping around my throat and my chest and squeezing. Shoving down on my head and my shoulders until I have to put my palms on my knees just to stay standing. My own brain is begging me to just let it end. Just let it take me down. Anything is better than feeling this way. Oblivion is a kindness when the only alternative is pain. All I have to do to make it stop is just submit.

“Submit.” I can’t tell if it said that to me or if it’s my own mind trying to shut down. Trying to escape.

Somewhere, on the other side of the darkness, my wife is at her computer. I can’t see her or hear her but I know she’s there.

“And every project you’ve left undone. And everyone who hates you and thinks you’re a freak. And the family who adopted you only to kick you to the curb when they found out what a disappointment you are.”

It’s got to be talking to me. It wants me to think I’m doing this to myself but I’m not. I know I’m not.

“And everyone who has to support your useless life because you’re too broken to contribute anything of value. You are a burden. A drain. Submit and let me have you.”

“Come and get me yourself!”

The pressure slackens. I take a breath. Then another.

“You can’t!” I scream at it. “You can’t take me if I don’t let you!”

I don’t care if it thinks this is fun anymore. I’m furious. Just this once, I won’t obediently slide down its gullet like a good little morsel. I’m going to dig my claws into its throat all the way down.

“You’re not Death. You’re not inevitable. You’re a parasite!” Wrath burns in my belly. “You’re so pathetic you can’t kill your own prey! You can only feed once you’ve convinced someone else to kill it for you!”

It’s not squeezing me anymore. There is pressure building, but it’s coming from inside of me.

“Tell me I’m wrong!” I raise my fists. “Answer me!”

My demands go unanswered.

“You don’t want a legend to eat do you?” I continue. “You can’t handle one. That’s why you don’t want me to live a long and full life. You don’t want me to leave a legacy because you can’t eat that!”

There’s a sharp sound. Like a gust of wind pulled backward. I’m terrified that I’ve made a mistake. That another assault is coming. But I can’t stop. If it has the power to end me then let it do it now. I’m so tired of living my life on my knees.

“You want complete victory. You want all of me, and you can’t eat other people’s memories of me.”

I’m right. I know I’m right. I have to be. I push harder.

“You can’t have all of Robin Williams because millions of people have seen him and laughed and they remember. You can’t have all of Chester Bennington because you can’t erase every recording of his voice. You can’t have all of Alan Turing because you can’t un-invent the Turing Machine and you can’t rip him out of millions of textbooks. We have the films, we have the books, we have the memories and you can’t swallow us all!”

It’s shaking now. I can feel it all around me. Tremors in the ground and in the air. I wait.

“You’re going to build a legacy then?” it says finally. The resonance in its voice is gone and it sounds farther away now. Above and behind me.

“Why not?” I answer. “I have nothing better to do with this life.”

“A legacy of what?” it scoffs. “Scooping cat litter? Sweeping floors? Fetching groceries and all the cute little tasks you think are so very essential and appreciated?”

“Everybody does chores,” I bite back. “And nobody finishes them all every day, every week, every month. Everybody has projects left undone. That’s not a sign of failure. That’s everyday life. Your expectations are unreasonable! And even if they weren’t, I’m not letting you set the benchmarks for me. What have you accomplished today, hm?”

Silence.

“Well? All you do is talk. Even I do more than that.” I’m warm now, I realize. I don’t think I’m actually wearing anything but even the clamminess of the ground isn’t reaching my feet anymore. I can’t tell if I can see a faint glow around me or if my eyes are playing tricks in the dark.

“Fine,” it sighs. “Maybe you’ll actually finish and publish one book before you die. Maybe five or ten people will actually read it. Maybe they’ll even enjoy it. But then their lives will end as well and no one will remember anymore.”

“Still one more book than you’ve ever written,” I snap. “Got anything else for me? Hm? These are schoolyard jabs and I’ll remind you that those didn’t break me either.” I’m almost sure I can see a faint outline of myself. Well, it’s a dream. Why not? I lift my chin and stare into the blackness.

“There is nothing you can do that will leave a lasting impact on this world,” it says. Irritation sharpens the words.

“Tell that to the guys I’ve talked out of suicide.” I bare my teeth in challenge.

“Two or three.” It scoffs. “I still have plenty of time to wear them down again.”

“I cost you a meal,” I say. “More than once. I bet that made you mad.”

It huffs, trying to dismiss my words, but I recognize the sound from the bullies of my childhood when the teacher came to end their fun.

“So two or three–”

“Five,” I interrupt.

“A few guys will remember you for a few years. That’s not a legacy,” it retorts. “A minor delay. That’s all. There are hundreds of thousands of others teetering on the edge of the precipice as we speak. I’m not going hungry any time soon.”

“I’m not done yet,” I tell it flatly.

“Excuse me?” I wonder if it has eyebrows to raise.

“I’m not done,” I repeat. “I’m not done talking and listening and helping. I’m going to take more than five out of your mouth.”

“You think I’m afraid of a deformed cripple with a saviour complex?” it laughs.

“You had better be afraid of a deformed cripple with a functioning sense of empathy and a personal vendetta against you.” I jab my finger in the direction of the voice and I realize I can see my hand. It’s faint but there’s a warm light there, enveloping my skin.

“Your life is already half over, human,” it snarls. “You are one tiny bump on the road, barely enough for me to feel let alone trip me up. You’ve wasted so much time cowering under my heel that you don’t even have enough left to make a difference among eight billion of your little pestilent kin. Do you have any idea how much effort that would take?” I feel a waft of air as though a hand sweeps in front of me in dismissal.

I cross my arms. “Only as much effort as I’ve been making so far.”

“Hah! How do you figure that?”

“One light in the darkness draws all eyes. That’s all I need to do, and all I need to be.”

Whatever it was planning to say, I seem to have derailed it. It gets out the first part of a word and stops. Finally, it speaks again. “That’s all very poetic and pretty but ultimately useless. Impractical. Be realistic,” it says.

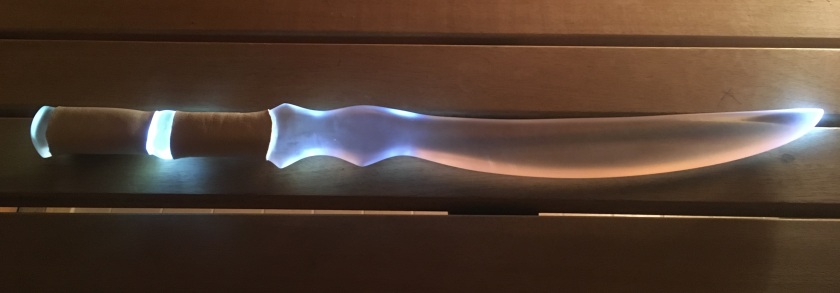

“You can’t even finish the project that’s been sitting in your workshop for two years now? And how long have you been working on that novel you care so much about? Do you really think you can save everyone?” it chides.

“No,” I say. I lift my chin.

“Then we’re in agreement.”

“I don’t have to,” I continue. It scoffs but I don’t give it the opportunity to get in another jab. “All I have to do is show them the truth. I will shine my light all over you and show them that the Black Dog of their nightmares is nothing but a bloated tick with a god complex. I will shine my light all over them and show them that they have value and beauty even if you told them they don’t.”

“That’s all very cute but …”

“I will show them how I fight!” I shout over it. “And they will know that it’s possible. They will fight you too.”

“And you’ll all get the laundry done in a timely manner?” it says. “Maybe lose a little weight on the treadmill? Or even … dare I say it … get a job? How heroic. I’m sure they’ll write songs about you.”

I ignore its attempts at mockery. I’ve heard it all before.

“We’ll all live long enough to die of something else.” I glare at it. I can see it now. Undulating clouds of darkness all around me. I extend my arm, pointing a finger at it. It retreats, avoiding my touch. “And you’ll get nothing. Because you aren’t Death. You’re a thief. You’re an unnatural interruption of life. You’re a carrion feeder.”

“Believe what you want,” it sighs. “I will outlast you and every other human in this world. I am eternal. Even if you could beat me, I always return.”

“You keep telling yourself that.” I slap it with its own words. “I hope you are eternal so you can live in starvation until the end of the universe.”

“You go right ahead and tell everybody your little story then,” it says. “There is not a single soul who will believe your ravings. You’re a mental case and they know it.”

“If only one believes, it is enough.” The fog is further away from me now. The light covers me like dragon scales.

“Is it?” The voice is smaller still. Only a few strains to it, as if only two or three people are speaking in sync. “You think it’s enough to support one person in this world? A single human that will ultimately forget your existence and then die?”

“I know it’s enough,” I say. “Or you wouldn’t be trying so hard to stop me.”

It struggles to say something but I’m done listening.

“You picked the wrong human to mess with, Depression.” The light is pushing it back and I can see the ceiling above my bed. I can hear my wife’s fingers on her keyboard across the room. “You can chew on me all you want, but you’ll never get the last bite. I will starve you. I will blind you. And if I ever get my hands on you somehow, I will make you wish you could die.”

Silence. Even if it tried to speak, it’s too far away for me to hear.

“This is my head and you’re not invited. Get out.”

As I woke fully and stretched, I smiled at my wife. Yeah, I slept through my alarm. Oh well. I decided to make the best of my day anyway. I don’t know how much work I’ll get done on my novel today but I will do some storytelling here anyway. I hope you found it interesting.

Oh, and if you see Depression around, tell it I said “the cafeteria is closed.” It’ll know what you mean.