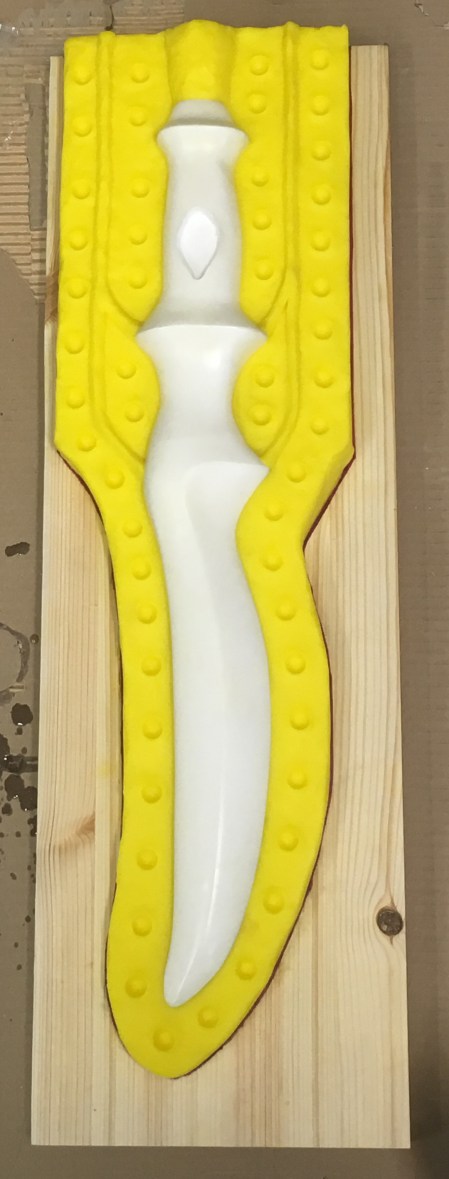

Otherwise known as the two-part mould. It’s half finished guys! Actually, it might be all finished right now; I have to go to the workshop to check. But I wanted to share with you the progress shots from last week because playing with goo is exciting!

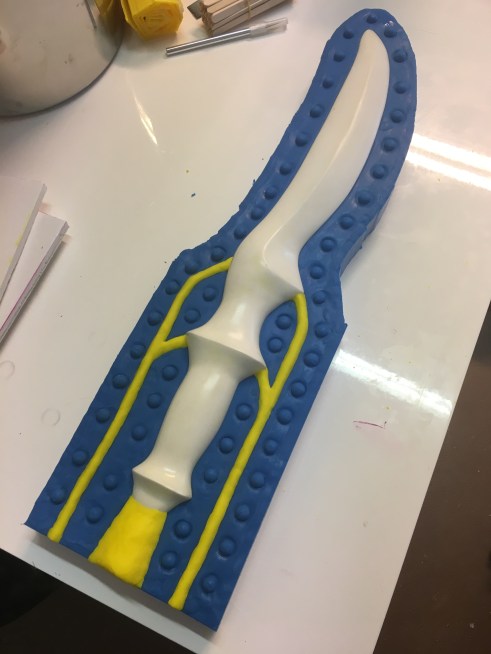

And it was all ready to go back in the box for the second half! Then I hit a few snags. First, since it’s the other side, the bendy part around the blade had to be put on the other way and when I did that, it somehow ended up about one centimetre shorter. I have no idea how this happened. Oh well! I just added some more corrugated plastic on the end.

Then, I noticed that the straight pieces of foam board I had used for the upper parts of the sword had become badly warped overnight! I tried to patch the gaps with extra hot glue but it just wasn’t working. I had to cut some MDA board instead and use that. That sucked up some extra time.

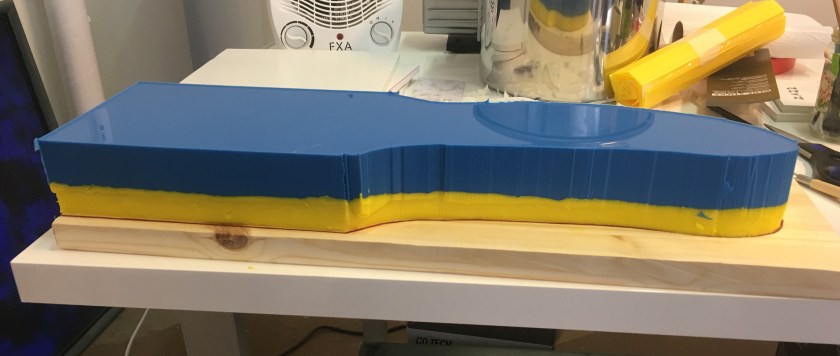

Then, as I was degassing the silicone for the second pouring, I realised something: it was really hot in my workshop. I thought it couldn’t be more than 24C or so in there and I was really focused on my work, not my comfort. BUT, with this silicone you can accelerate the curing time by increasing the temperature. Handy right? Except when all the bubbles aren’t out of it yet and it’s starting to set! AHHHHH! By the time I noticed what was wrong it was already as thick as cookie dough. I had to stick my gloved hand INTO the bucket of silicone and pull it out glob by glob. It even started curing to my glove and I had a big hand-sized blob of blue slime dangling off my fingers as I desperately waggled it, trying to get it off. It eventually plopped into the mould box with the rest.

So … will it be okay? I don’t know! The top of it won’t be as smooth and glossy as the top of the “Ikea cake” picture there. I’m afraid the silicone had already thickened so much that the last blobs that fell in will probably stay as they are and make the surface bumpy and weird. What does that mean for me? Well, it just means that I’ll have to do a fibreglass jacket around the mould instead of a wooden clamping box. Oh well! I have the stuff to do either one and I was on the fence about which way I wanted to do it anyway.

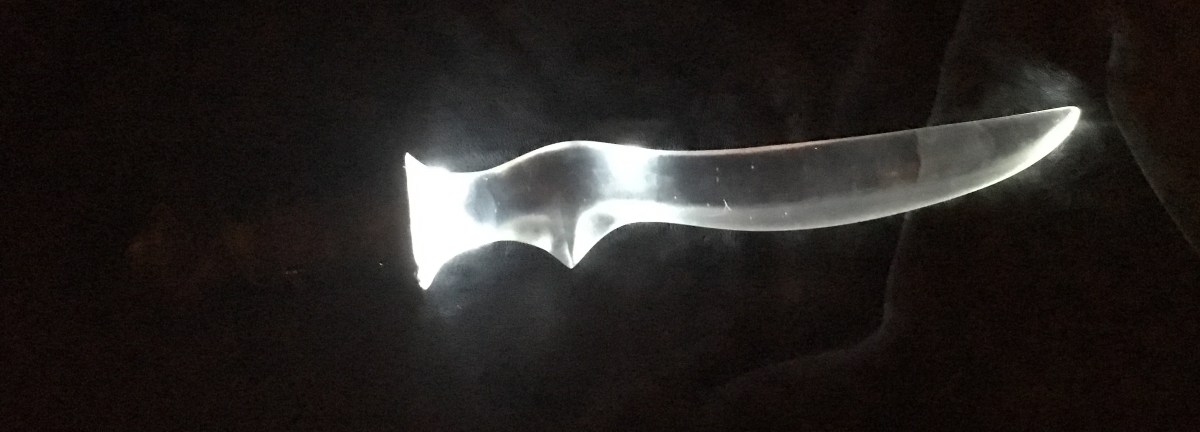

The real question is: did it cure nicely against the SWORD? Because if there’s bubbles or spaces against the sword, I have to do this part of the mould again. I’m making a pretty new mother mould for every Clariel model sword that will come from my shop. If there’s a mistake in that mould, there will be a mistake in every sword it produces! And I’ll have to take time to fix each and every one. That would ruin the point of making a better mould in the first place! It’s gotta be just as perfect as I can possibly make it.

Wish me luck! I have a feeling I’m gonna need it today.

![IMG_2546[1]](https://heythisismyjob.com/wp-content/uploads/2018/05/img_25461-e1525677645478.jpg?w=840)

![IMG_2550[1]](https://heythisismyjob.com/wp-content/uploads/2018/05/img_25501.jpg?w=573&h=764)