So the doctor didn’t say that I couldn’t go back to work when I had my last checkup. I may have ‘accidentally’ forgotten to ask. I have been bored to tears sitting on my duff, waiting for my silly body to fight off infection and heal up properly. All I’ve wanted to do for the past three weeks is just go to the workshop and make stuff!

Yesterday, I did just that!

![IMG_2201[1]](https://heythisismyjob.com/wp-content/uploads/2017/11/img_22011.jpg)

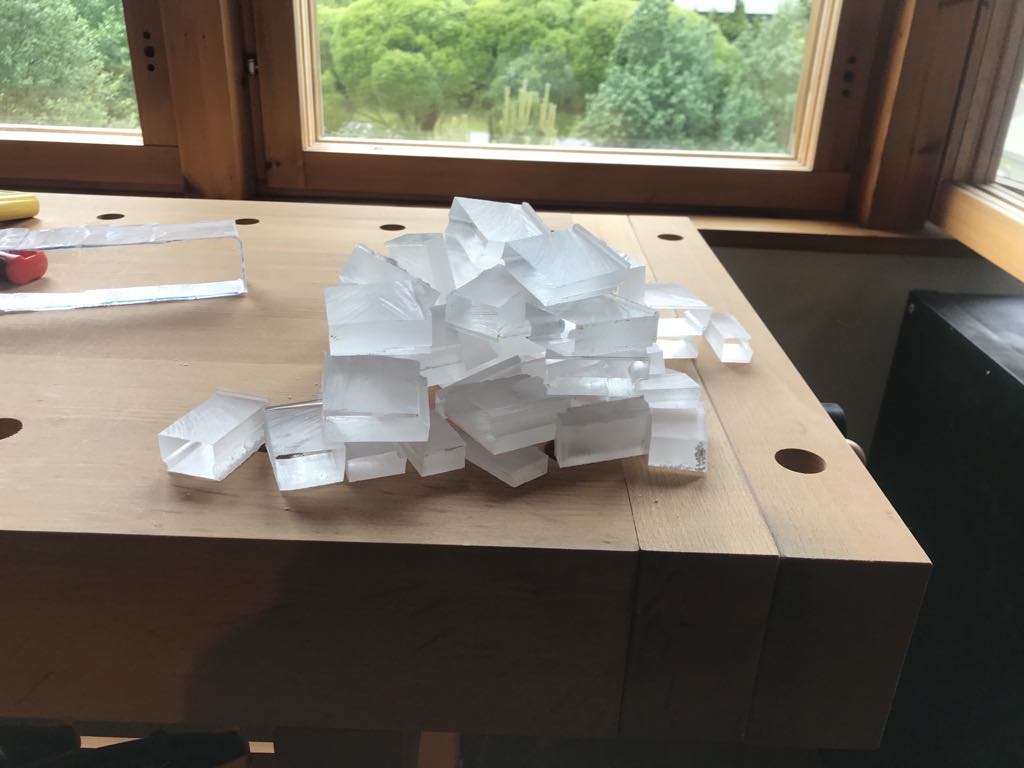

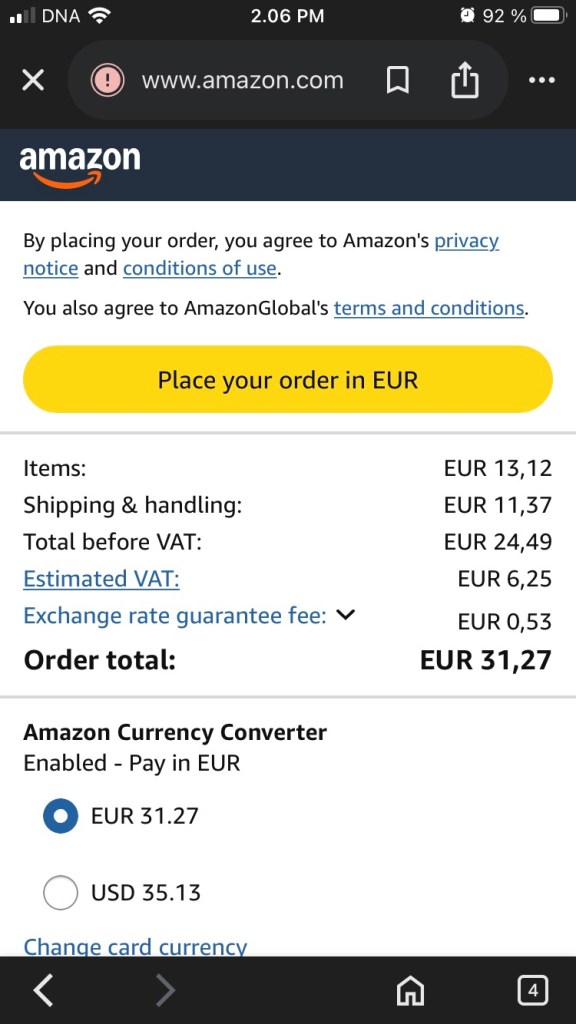

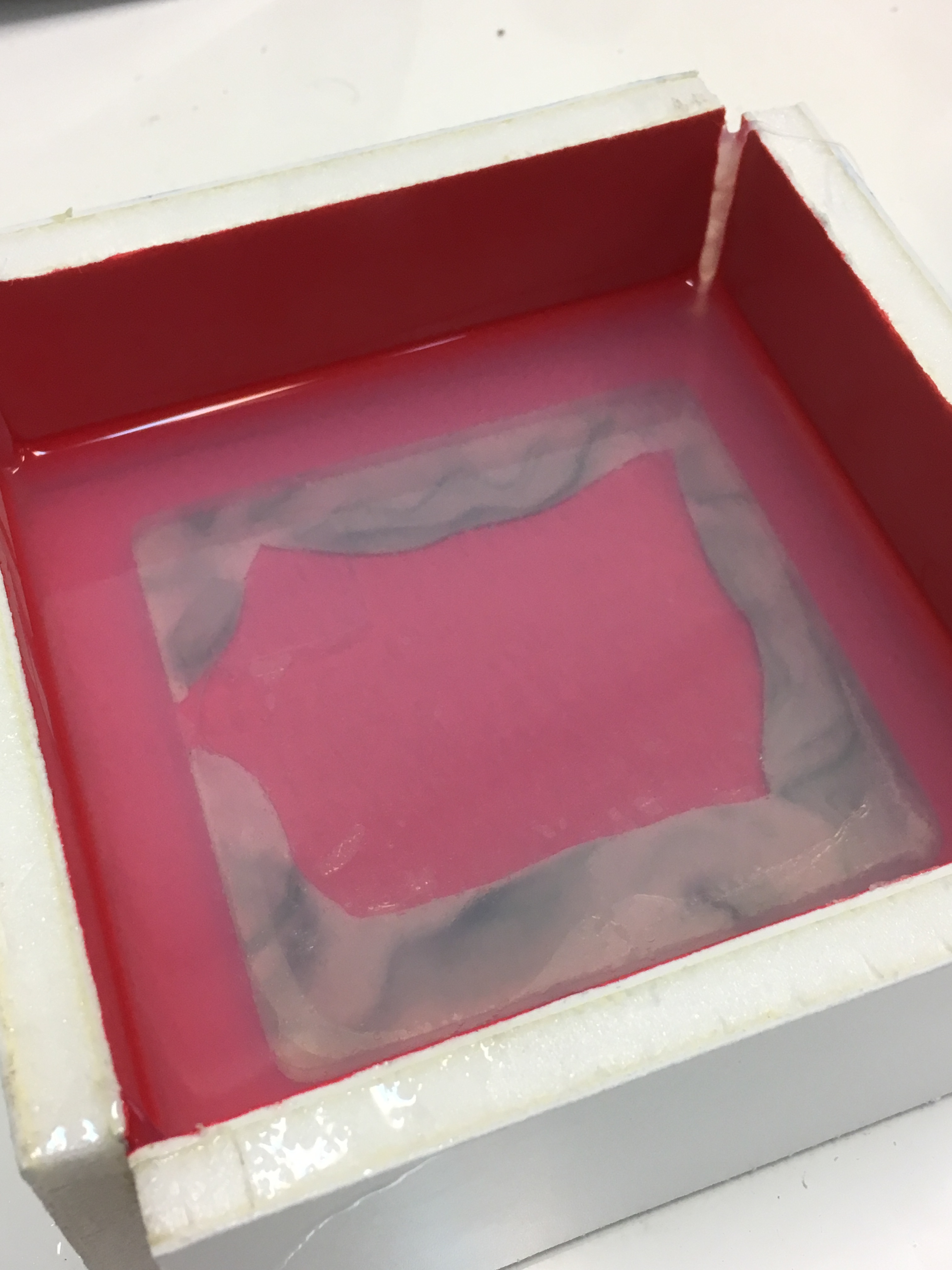

The heck are you doing Ethan? That’s not a sword.

Yeah I know it’s not a sword, but here’s the thing: silicone and resin are both really expensive materials and I’m using a lot of new equipment at this point. So I realised I needed to do something small first to make sure that everything is working properly and the materials are doing what I expect them to do.

This’ll be a little sci-fi computer chip thingy that I can use as a coaster on my desk. I’m going to be testing out the silicone moulding compound, the Alumilite resin, and the resin dye that I bought. That’s right! This will be the first time I’ve done transparent resin in another colour! I’m excited. 🙂

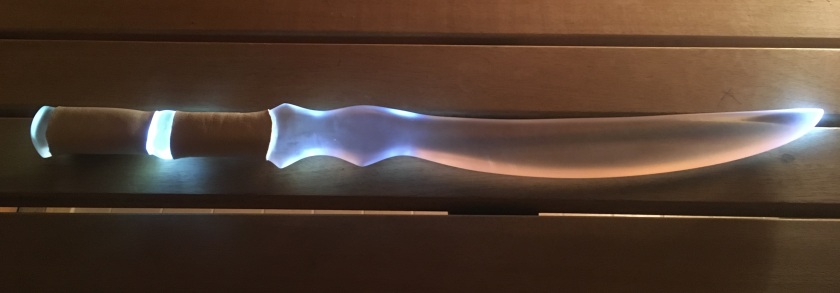

I’d also like to take a moment to thank all of you who have been poking me for sword commissions. I’m so, so sorry for taking so long to get back to you. I’ve been struggling with this medical thing and it’s been no fun at all. I’m going to ask my doc if it’s at all possible to postpone the next surgery until the new year so I can continue working at my job for the rest of November and the month of December

I’m definitely not in danger of losing my workshop. I just want to make that clear so you don’t have to worry about that. But it would be really nice to at least be able to cover the cost of my rent with sword sales instead of taking it out of my own pockets as I’ve been doing.

I also want to reassure you that the medical thing isn’t a degenerative condition or anything. It’s just a quirky little birth defect that we’ve been working on correcting to give me a better quality of life. 🙂 The only reason I’ve had to go back for more corrections is because there were some complications with the healing. Apparently, the body took offence to the doc trying to do too much correction all at once so we’ve had to slow down and do the fixing-up in smaller steps.

That’s rather annoying for me cause it means I have to keep taking time off work for two weeks here, three weeks there to heal from each stage. As anybody who knows me well enough can tell you: I am not good at sitting around doing nothing all day.

In other news: the metro station near my house has opened up and that means I can get to and from work much more easily and much faster. Yay for less travel time! Instead of waiting for a bus, taking the bus to the nearest metro stop, taking the metro to the neighbourhood where I work, and then taking a bus from there to as close to my workshop as I can get, I can simply take the metro from home and skip the whole first bus leg of the journey.

Speaking of journeys … workshop tiiiiime! The workshop is my happy place and I can’t wait to get there and make some cool stuff! Catch ya later guys.

![IMG_2229[1]](https://heythisismyjob.com/wp-content/uploads/2017/12/img_22291-e1512719051664.jpg)

![IMG_2231[1]](https://heythisismyjob.com/wp-content/uploads/2017/12/img_22311.jpg)

![IMG_2201[1]](https://heythisismyjob.com/wp-content/uploads/2017/11/img_22011.jpg)