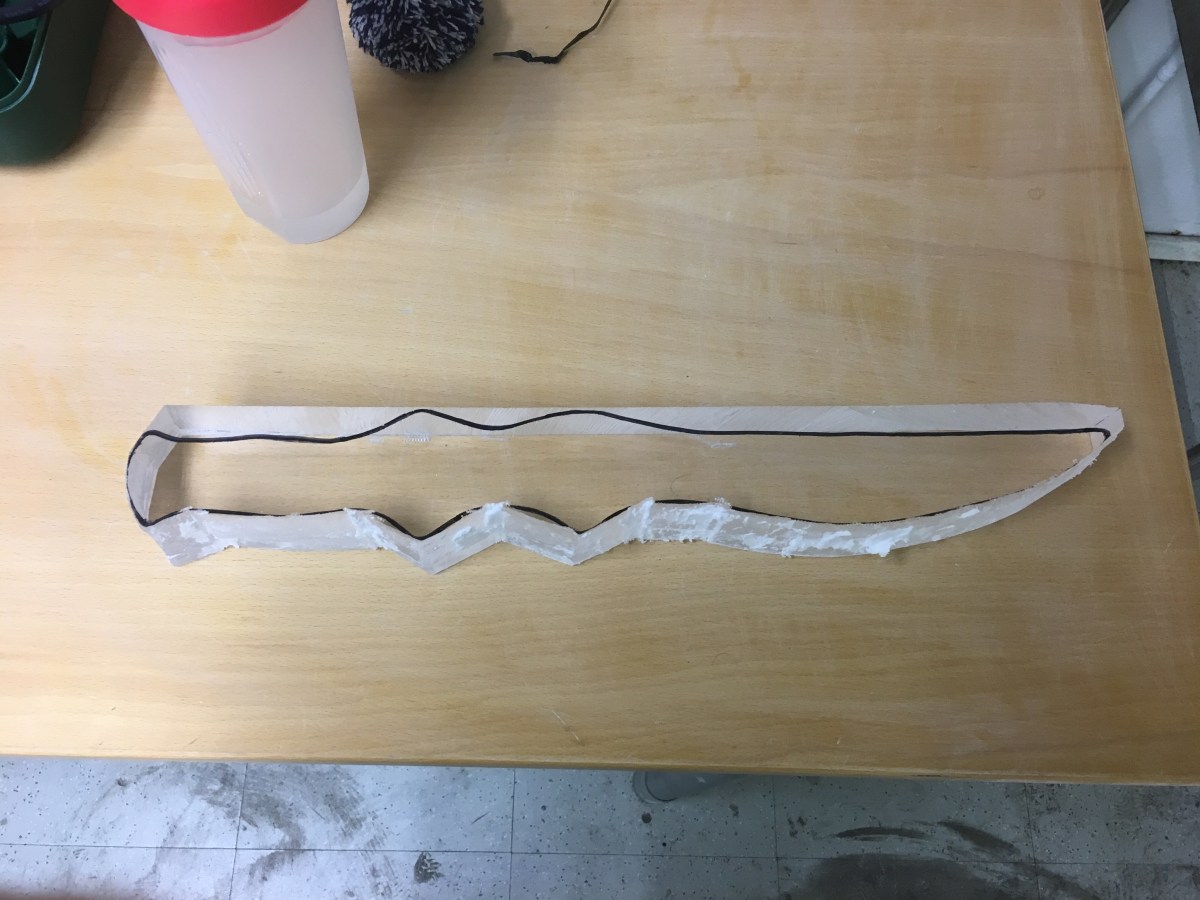

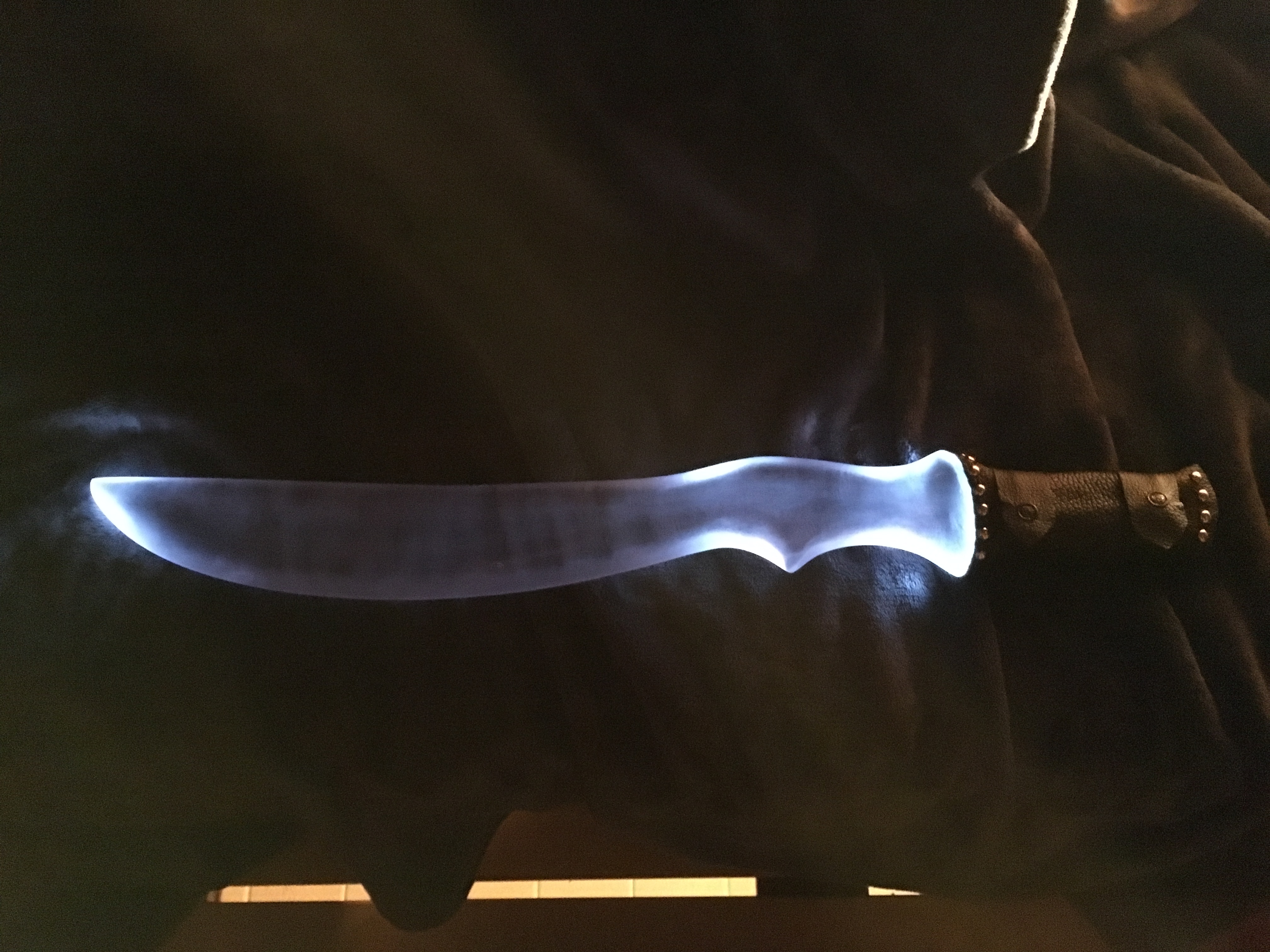

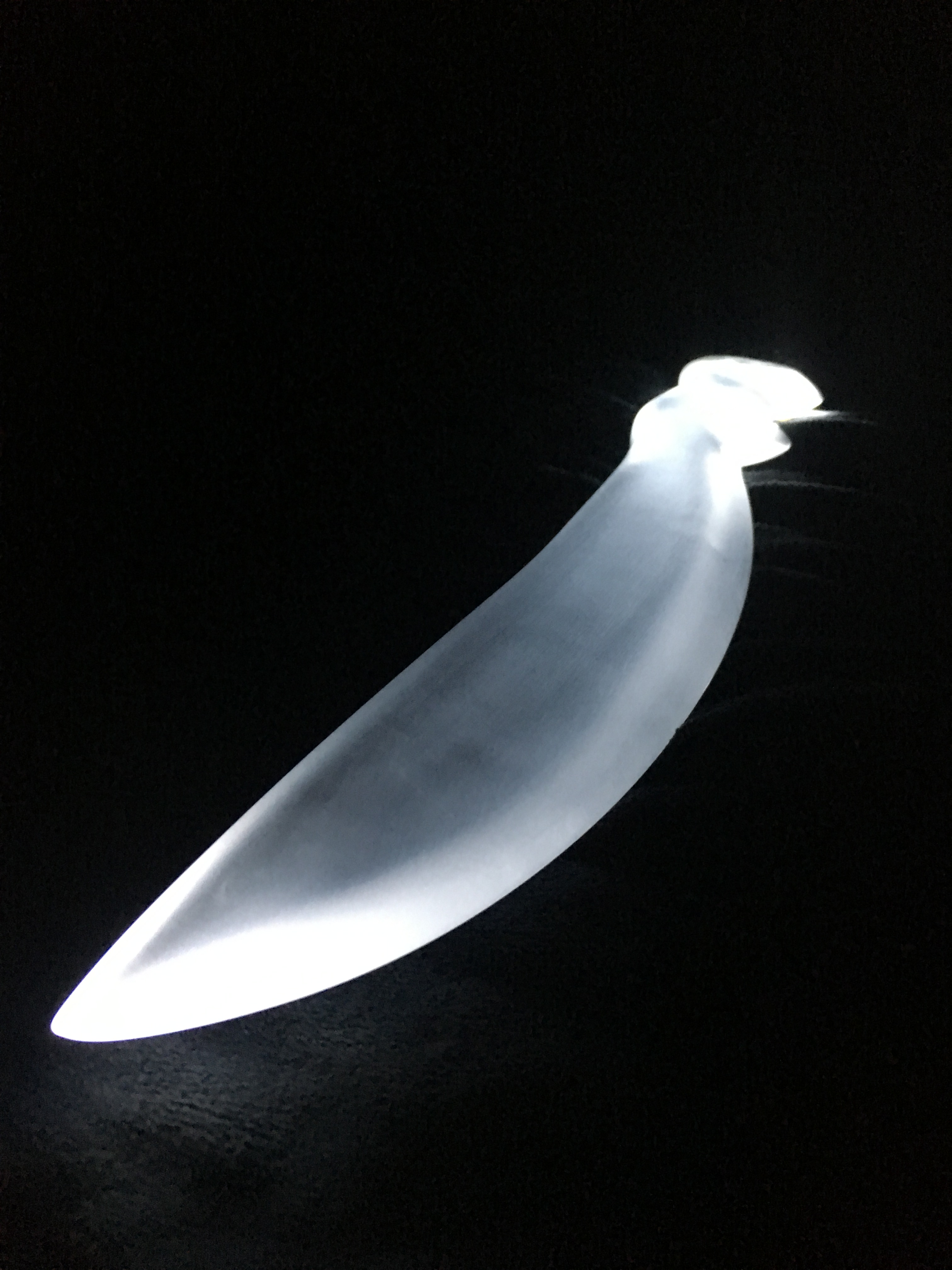

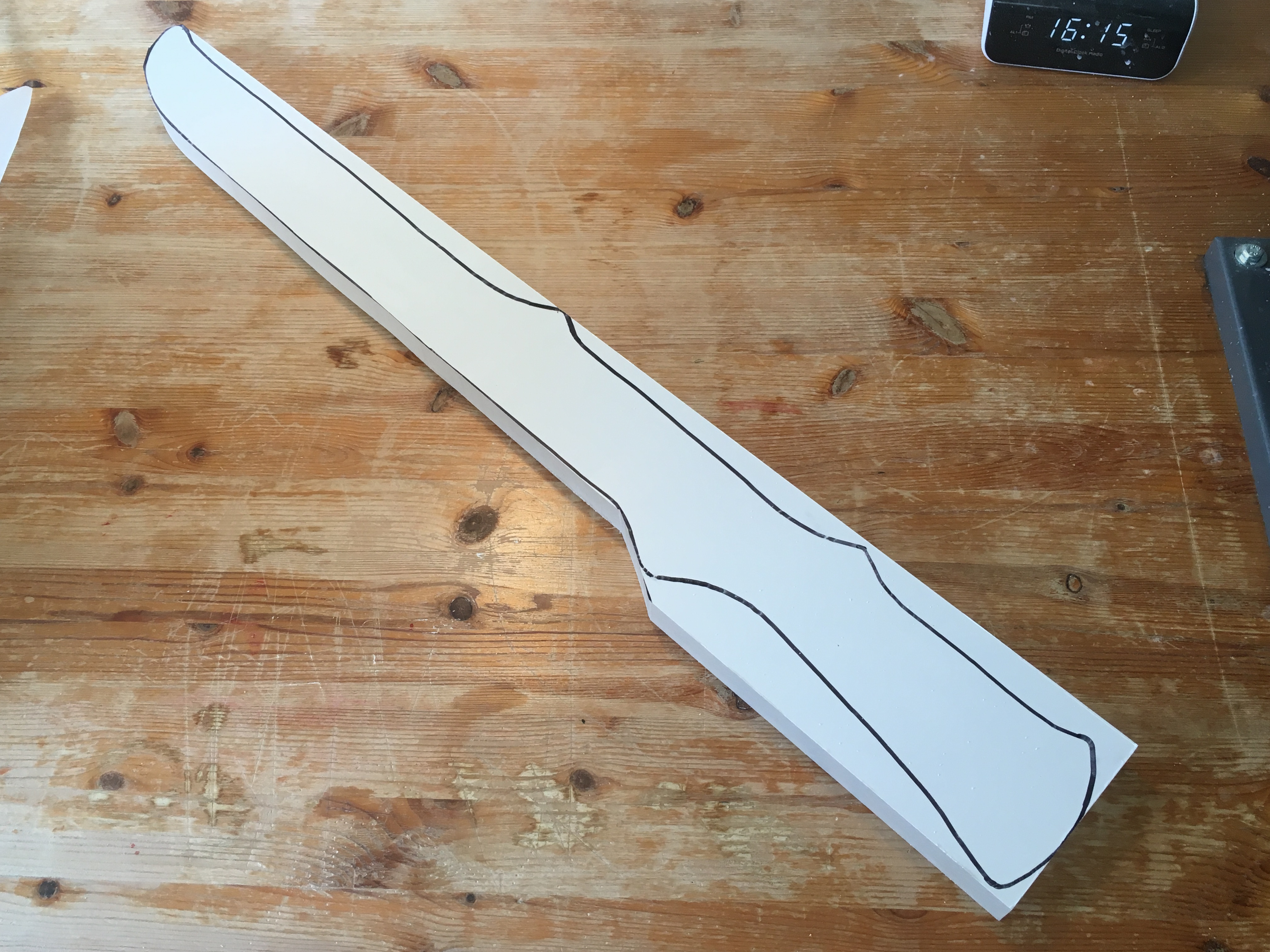

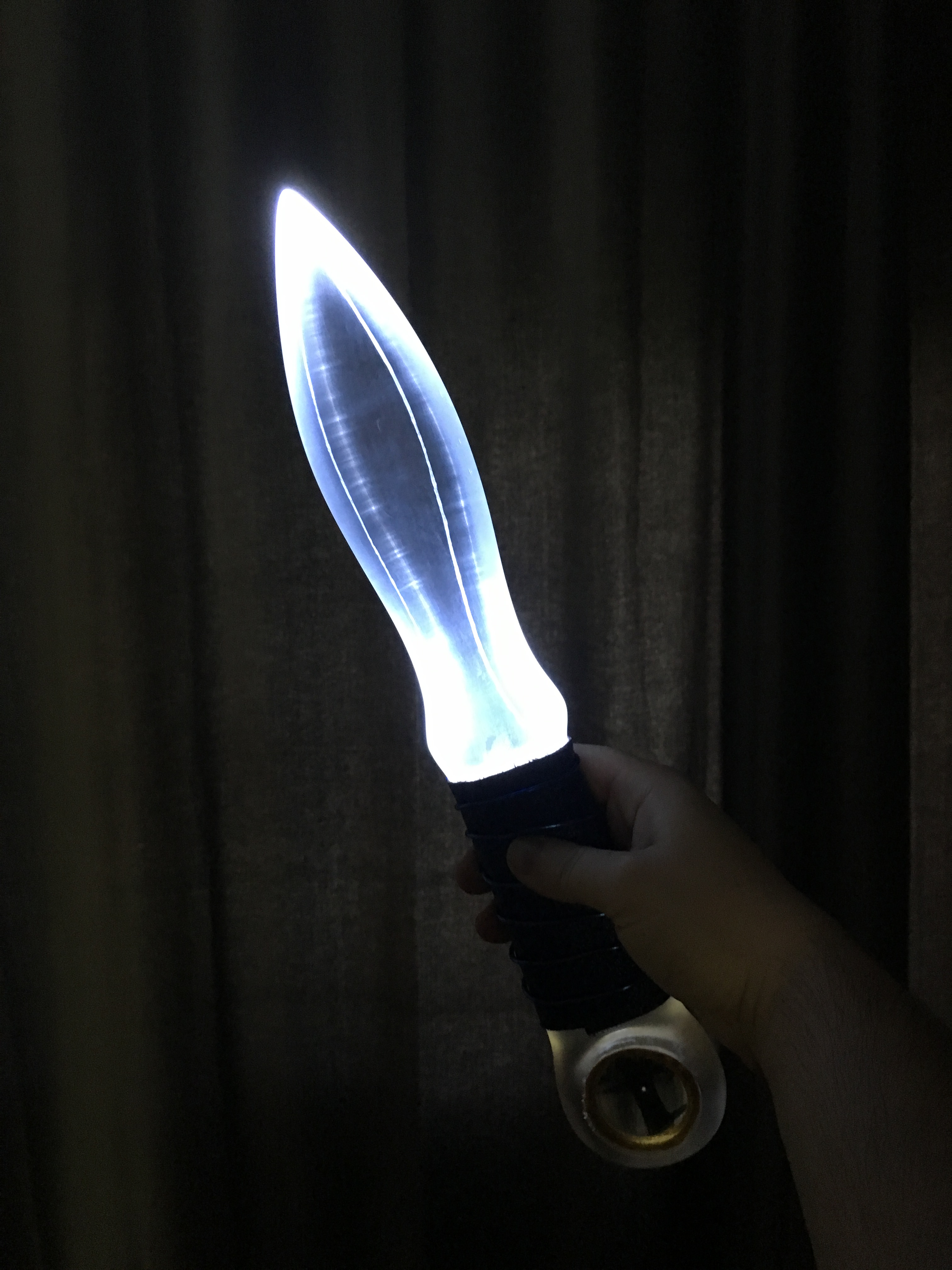

Got the modified Clariel seraph blade cut out as much as is practical with the plunge cutter. Now it’s time to tackle the wakizashi.

Slow and steady wins the race. There are several factors that dictate the pace of carving PMMA (Plexiglas).

For me, the first consideration is how much work my body can do each day. Because I’m not well, I have strict limitations on my endurance. I still have to do other things each day like prepare food, shower, clean, take care of my cats, and go grocery shopping. If I use up too much of my energy or raise my pain level too high, I won’t be able to do some or any of those other things.

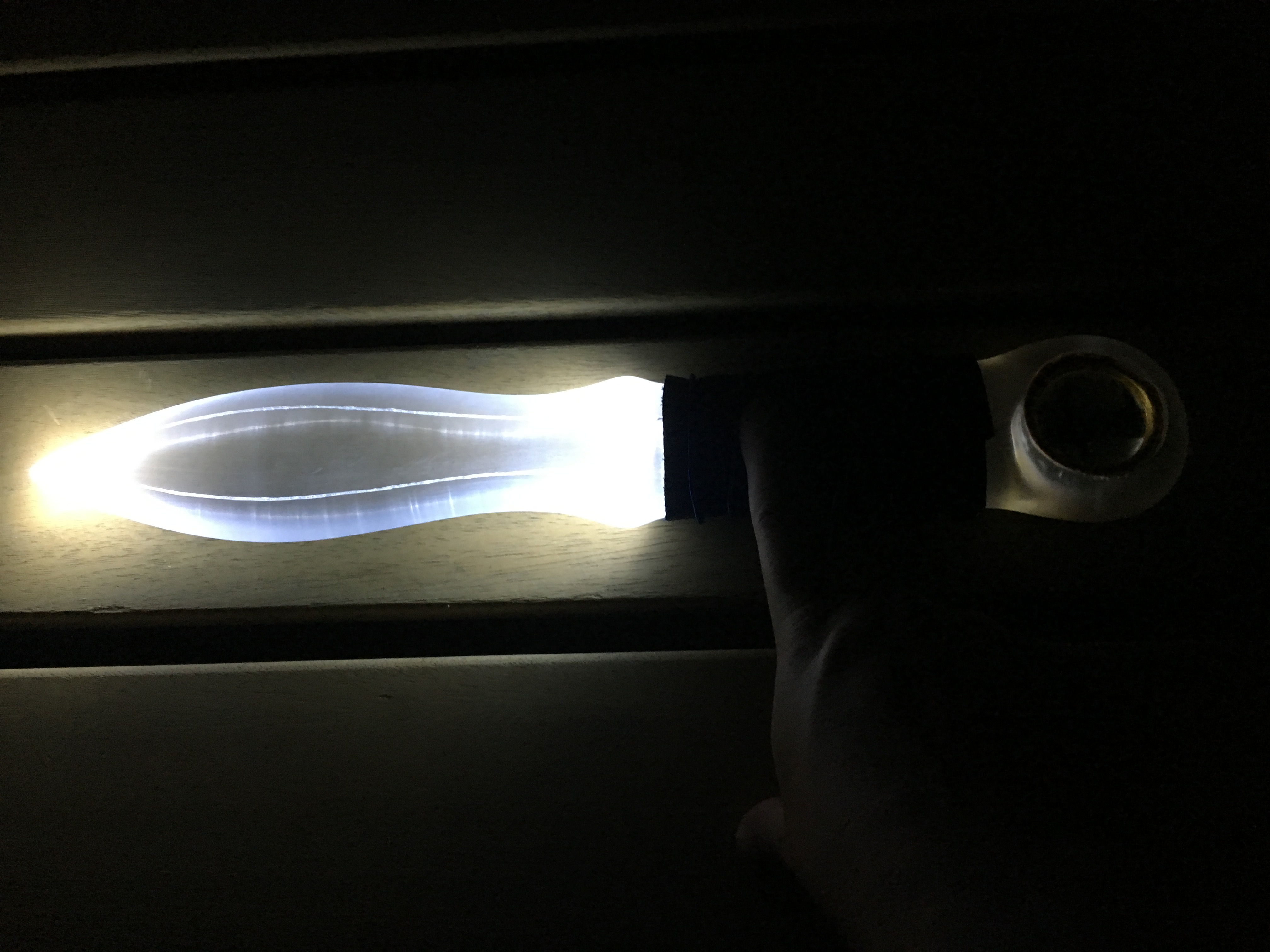

The second consideration is the nature of the material itself. Unlike wood, PMMA will begin to melt if it gets too hot. This will deform the piece you’re trying to make and, if you ignore the warning signs of overheating, it can actually discolour the plastic.

To cut PMMA, you need to use friction. Whether you’re using a saw, a grinder, or a sander, the problem remains. You will have to go slowly and give the material adequate time to cool down during the cutting process. You must work in stages and keep moving the tool to different parts of the piece.

The third consideration is the tools themselves. I consider my Bosch multitool to be a decent machine but even it overheats after a few hours of work. It needs time to cool down as well. It’s also possible for the teeth of the tool to get gummed up with melted plastic and it will need to be cleaned.

Vibration from the cutting tools can cause numbness, tingling, and even nerve damage if used for a prolonged period of time. This can be partly mitigated by keeping the cutting bits clean and sharp. The one I’m using needs to be replaced but I’m having difficulty sourcing Bosch starlock cutting bits in Finland. Ah, the joys of living in a remote corner of the world.

Slow and steady; we’ll get there eventually.