So, in all my years of doing this crazy job, I’ve never had a sanding belt break. Today, I had two of them fail on me.

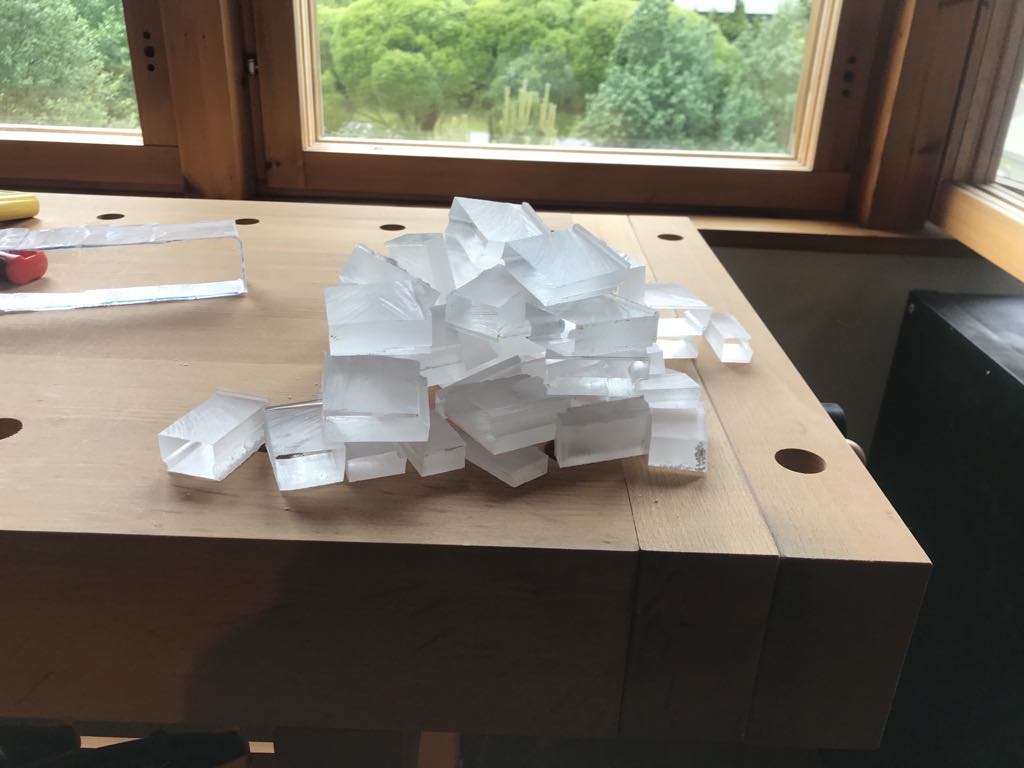

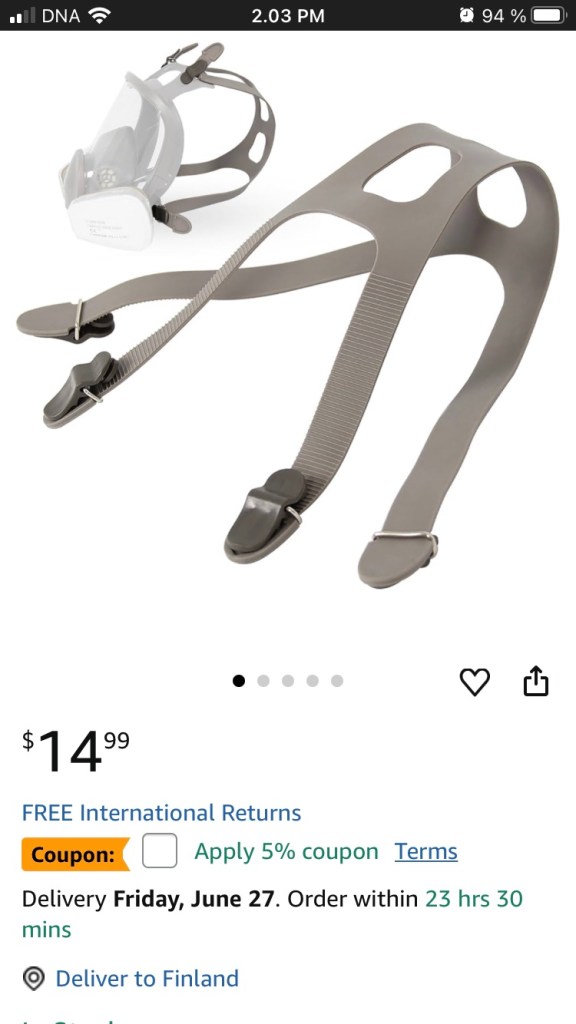

Both of them failed in the same place. Right at the seam. I don’t know if it’s because they’re old or because I should have used a coarser grit for this stage of shaping or some other reason I’m not seeing. What I do know is that Those were my last two belts and I’m not sure how I’m going to finish the project. I’m not exaggerating when I say I’m broke right now.

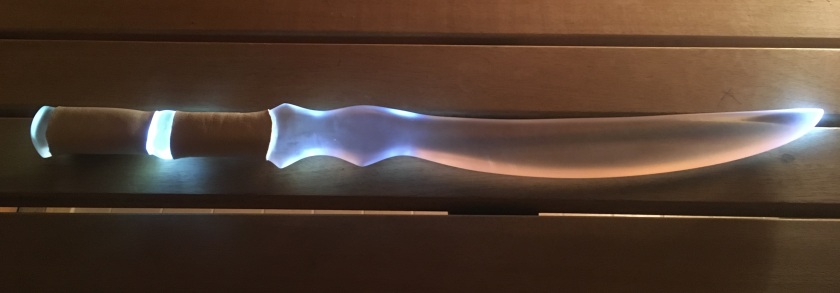

The good news is that I got the seraph blade all sanded around the edges and I can at least get it measured and marked up for shaping. It’s really important that all those edges make a nice 90 degree angle with the sides (which we know for sure are flat). That lets me make sure I get the edge of the blade right in the middle and not curving off in one direction or the other.

So what now? Well, I shut my machine off and cleaned up the workshop, swore at the broken belts (as is customary), and went for a shower. Now I’m gonna work at clearing my head and conferring with my wife about what sort of budget we can spare for this project. I can’t afford to sink money into it until it’s done which was my way of doing things before financial disaster hit us.

Wish me luck. I’ll try to find a way forward.